egeplast piping systems for sewage disposal

Just like Drinking Water Pipe Systems, sewage pipe systems have to meet the highest requirements, with operational safety and long-term leak-tightness being the top priority. Accordingly, egeplast, one of the leading manufacturers of PE sewer pipes for municipalities and industrial applications, exclusively sells top-quality pipe systems. Our high-grade sewage pipes ensure a safe removal of waster water, rain water and industrial water, both for pressure sewer systems as well as for gravity pipeline systems. Trust in our expertise around professional waste water disposal solutions.

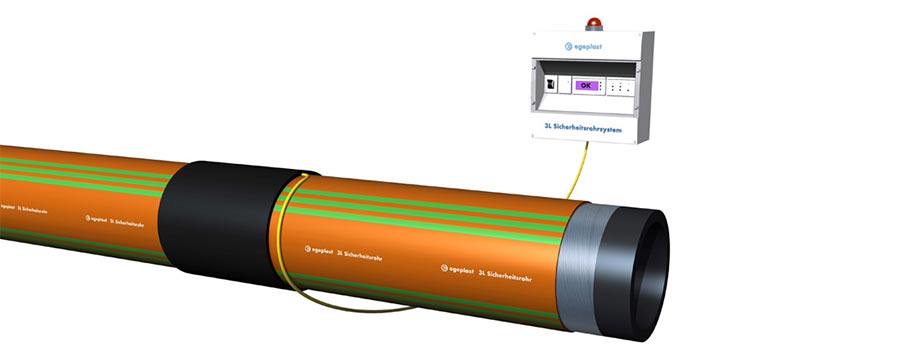

3L leak control pipe system: Permanently or intermittend monitored piping system that finds and reports damages

The 3L safety pipe system provides a 100% leakage monitoring for soil and water protection. It has been designed to report and locate damages – even on a mains-independent basis – and can be accessed and controlled in real time via the internet. A monitoring unit conntected to the pipe emits an alarm even by the smallest damage to the pipe. Messages will be sent directly to the control centre or to the smartphone. It can automatically switch off connected pump systems, thus preventing disasters reliably and at an early stage.

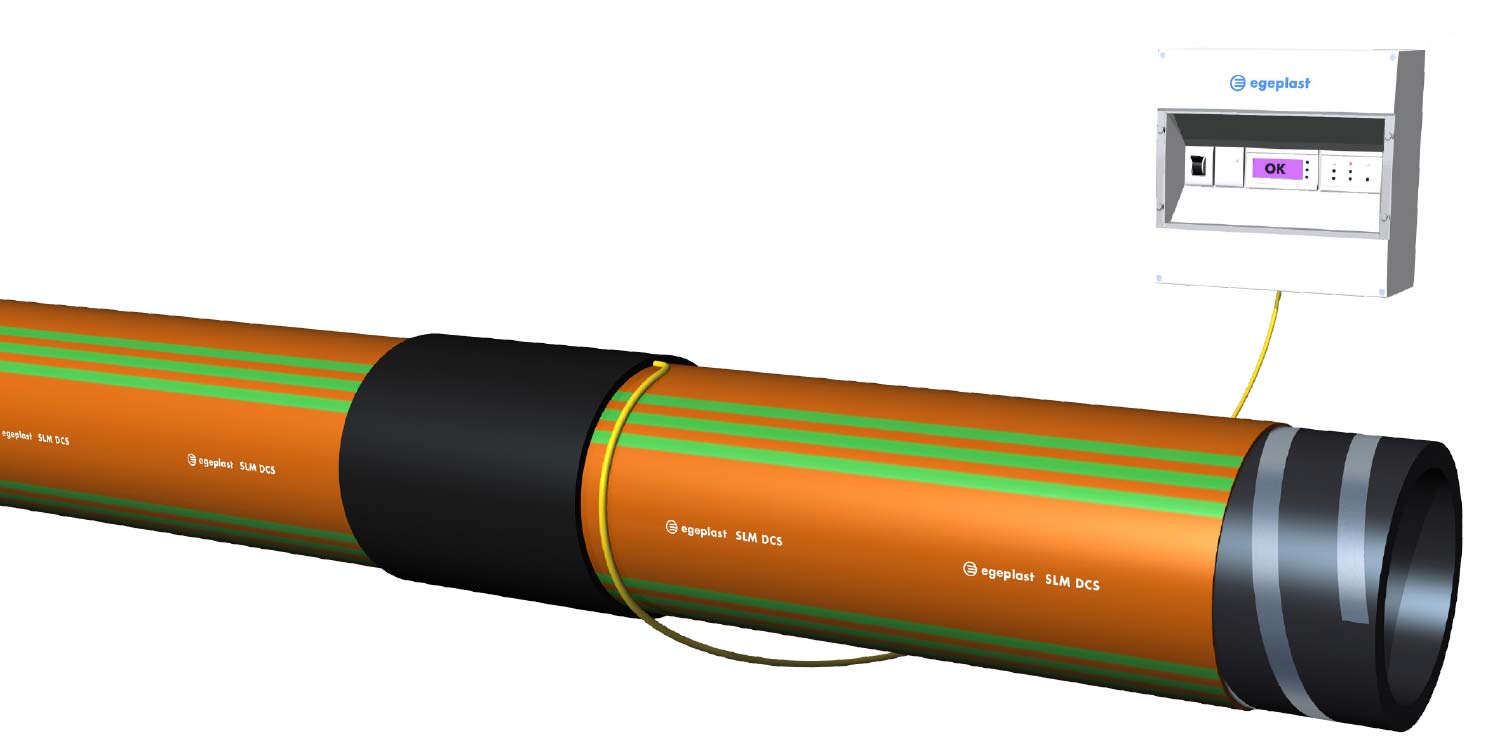

Early Warning System for the Protection of Sewage Transportation Pipelines – SLM® DCS

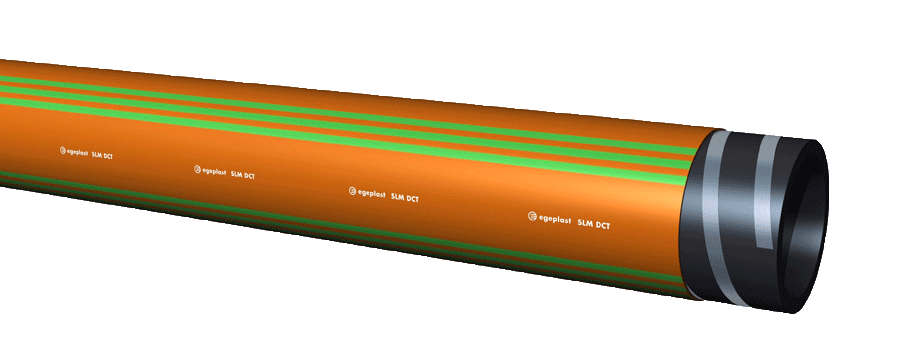

SLM® DCT: Piping system with integrated quality test for closed construction

SLM® 3.0: Protective piping system for damage-free installation

SLM® 3.0 piping system is a patented, multi-layered protective piping system of the latest generation. When installed by means of alternative installation techniques, the protective pipe ensures the grid operator longevity and efficiency. Engineering offices and contractors verify flawless planning with this piping system.

SL® Sewage pipe system

The egeplast SL® sewer pipe is made of PE 100 according to DIN 8074/75. For the production of the solid wall pipe

the most modern polyethylene materials are used.

To ensure optimum conditions for camera inspection, the pipes are manufactured with an inspection-friendly light-colored inner layer using the coextrusion process.

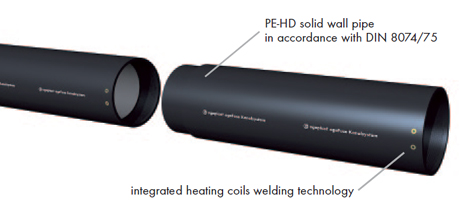

egeFuse® 2.0: Welded PE system with integrated welding technology

With the egeFuse® 2.0 gravity sewer system made of polyethylene, pipe and jointing technology are delivered at the same time – as one component – to the jobsite, where spigot end and weldable socket ends are integrated. The high ductility of the used PE enables subsequent operation of the sewer without any cracks or breaks.

egeModul PE: Short pipe module system for replacement of older sewers by relining technique

egeModul PE is a short pipe module of polyethylene with a high density (PE-HD) for rehabilitation or replacement of damaged sewers. The high ductility of the applied PE-HD enables long-lasting operation of the rehabilitated sewer.

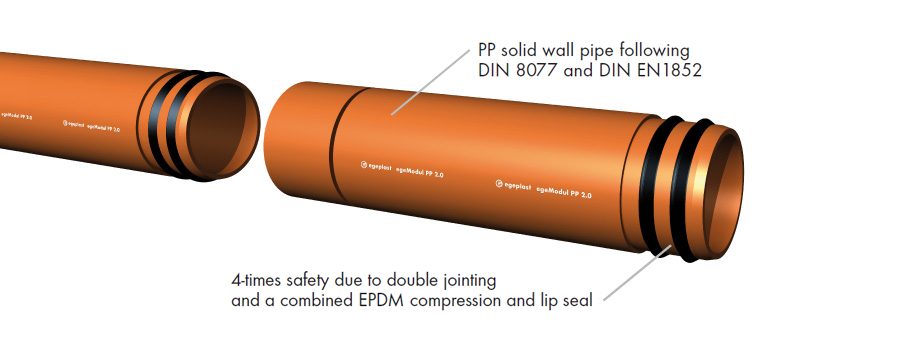

egeModul PP 2.0: Short pipe module system for replacement of older sewers by burstlining and TIP techniques

egeModul PP 2.0 is a short pipe module of polypropylene for rehabilitation or replacement of damaged sewers. The filler-free material PP ensures acceptance of highly static loads and represents durability and effiency.

egeFit®: Components and moulded parts according to specifications

egeplast offers segmented moulded parts, manufactured from piping, also designed according to the pressure class and requirements. All moulded parts can be delivered in the desired function (SLA®, DCT, 3L, egeSlurry® or similar). Entire assemblies, consisting of pipe and/or moulded parts, can be designed and prefabricated according to customer specifications, in order to facilitate your work at the jobsite.