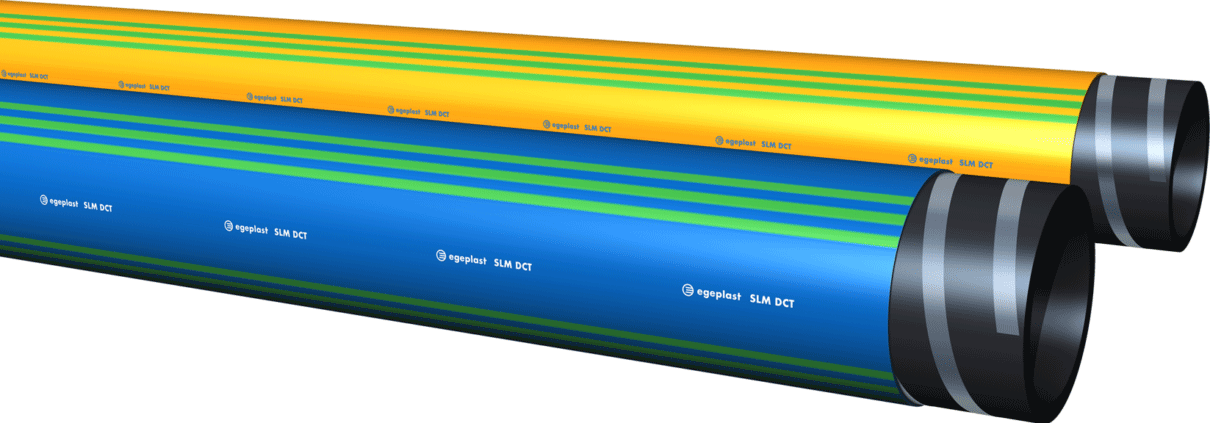

SLM® DCT

Piping system with integrated quality test for closed construction

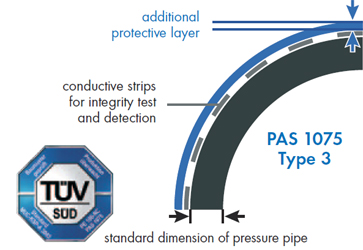

SLM® DCT is a piping system of PE 100-RC with additional protective layer and integrated conductive strips. These enable testing of the piping system for integrity directly after installation. In addition, they offer the possibility of permanent detection of the installed line.

additional protective layer made from PEplus

inner pipe made from PE 100-RC

conductive strips for pipe detection and integrity check

Product features

- Integrity test of the piping systems for acceptance of the construction work

- Increased safety during operation

- Permanent detection

- Trenchless installation techniques are possible without shortening the lifetime through damage or reduction of the safety factor.

At a glance

Medium

Potable water | gas | wastewater | industrial media

Material

Core pipe, calibrated and signed, of PE 100-RC (Resistance to crack)

Protective layer of modified Polyethylene PEplus

SDR

SDR 17,6 – SDR 7,4 (others by request)

Application

House connection pipes | supply and sewage pipes | transport pipes | industrial piping Systems

Target Groups

House connection pipes | supply and sewage pipes | transport pipes | industrial piping Systems

Dimension

OD 25 – 1.600 mm

Connection Technology

Butt welding | electrofusion | mechanical joints

Approvals

DIN 8074/75; EN 12201; EN 1555; DVGW GW 335-A2; PAS 1075

Product Limitations

Pressure to PN 16 for water and PN 10 for Gas;

For operating pressures beyond that see HexelOne® DCT

Product Structure | Installation techniques

- integrity test after trenchless installation as well as the possibility of permanent detection

- black-box installations such as horizontal directional drilling, burstlining, relining and soil displacement

- open trench installation without sandbed, ploughing and milling

- open trench installation in sandbed