egeplast to co-operate with Pipelife Norway

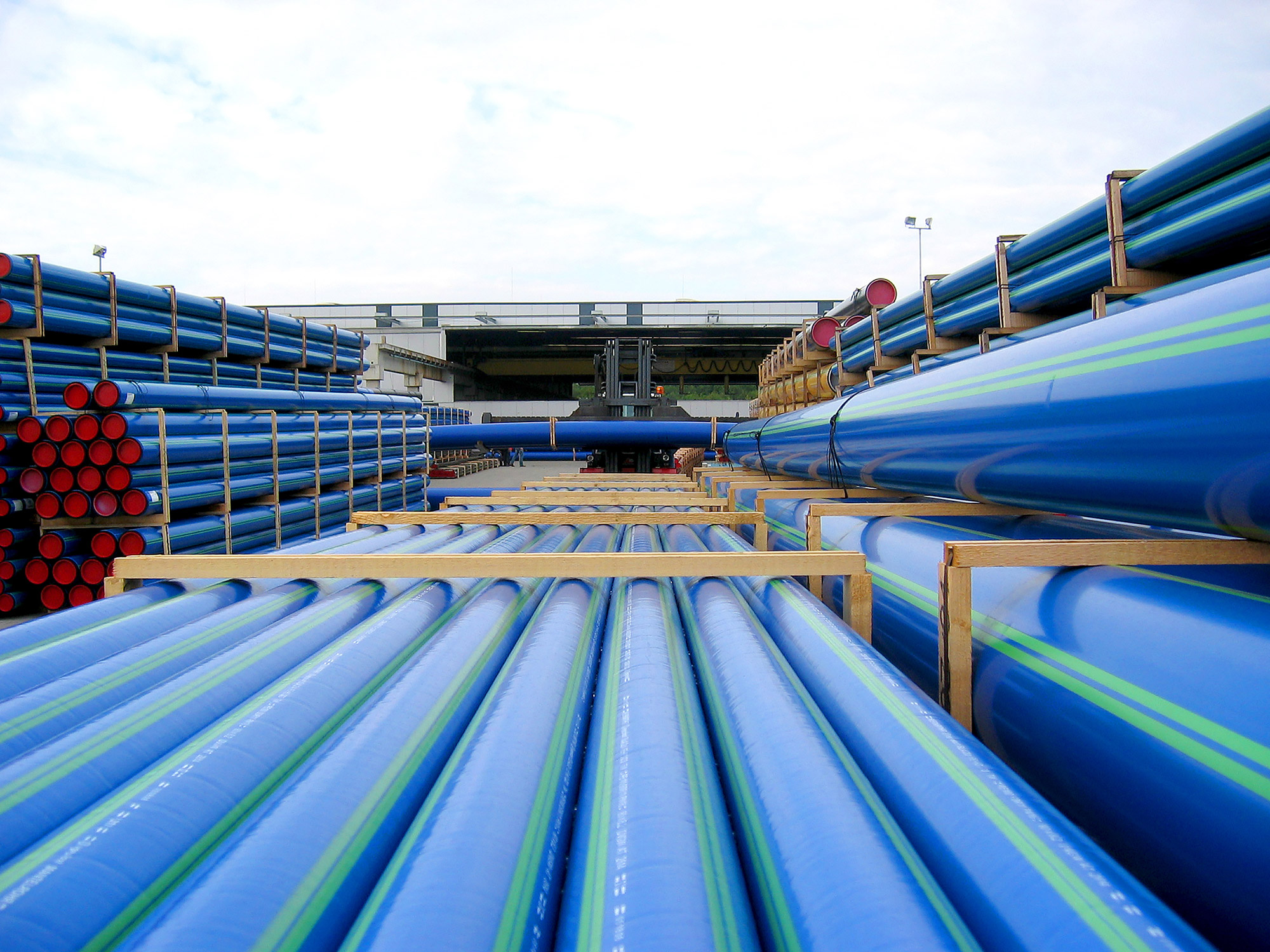

egeplast and Pipelife Norway have launched a co-operation for the SLA® Barrier Pipe. This agreement is applicable for the Norwegian market and is associated with significant customer benefits. Pipelife is about to establish a large warehouse with SLA® Barrier Pipes at its manufacturing site in Stathelle (South Norway). Full-truck transportation helps to lower freight costs to Norway, while small quantities can be delivered to the municipalities in Norway promptly and at low cost from the Norwegian warehouse.

“We are looking forward to finally being able to expand our product range for PE-pipeline systems”, Pipelife expert and project engineer Jan Kenneth Bartolo commented. The permeation-tight pipeline system made by egeplast will be available from strock from Pipelife in Stathelle shortly. “The trend towards permeation-tight pipeline systems has been increasing both in Norway and in Europe, and we are expecting an increase in sales”, says Raymond Molund, egeplast Sales Manager in Norway.

What does that imply for our customers?

Customers in Norway will benefit from this step, since it gives them access to an even wider range of PE plastics pipes for their projects, including permeation-tight pipe systems, and also because Pipelife is equipped with a large sales team. The fact that the pipe system is stored in Stathelle also makes logistics so much easier. Shorter and faster transport pathways to our customers help to bring freight charges down. In addition, Pipelife plans to contribute special orders for permeation-tight pipes and fittings, since it commissioned a new welding shop last autumn.

What are permeation-tight pipeline systems and when should they be used?

Clean drinking water should be transported to everyone, irrespective of whether people happen to be living in densely populated or remote areas. The water pipeline systems run through various kinds of soil. In severely contaminated soil, drinking water must be protected from any ingress of pollutants through the pipe wall. Under these circumstances, a permeation-tight pipe prevents contaminants and chemical substances from penetrating into the pipe and impairing the quality of the water with regard to its smell, taste or other forms of contamination.

Although there is no immediate need for this type of protective pipe for water pipelines unless the soil features a significant degree of contamination, we have witnessed that the trend towards permeation-tight pipes has been increasing. The reason behind this is that some municipalities in densely populated areas have made permeation-tight pipelines mandatory and included them in their standards.

Molund explains this phenomenon by stating that since the useful life of underground pipelines exceeds one hundred years, many municipalities want to be on the safe side with regard to potential future soil contamination. In this context, economic considerations are vital, since it is very costly to unearth pipeline systems before the end of their service life.

Permeation-tight pipes can also be used wherever polluted water needs to be transported. Here, the intention is to prevent any pollution from the water from penetrating into the soil, which is mainly required for in industrial applications.

Barrier Pipes

Since 1985, egeplast has been manufacturing its permeation-tight SLA® Barrier Pipes. They are manufactured in Greven, Germany. The pipes have been certified by Nordic Poly Mark and DK-Vand.

Authors contact details

Raymund Molund

Email: raymond.molund@egeplast.de

Telefon: +47 4834 2558