The pipe system with integrated welding technology – egeFuse® 2.0

B_I Medien (www.bi-medien.de) recently published a construction project report on the renewal of a sewer of the Wesermünde water board. The sewer pipe system egeFuse® 2.0 proved to be the most optimal solution. All information about the construction project, the challenges on site as well as the implementation can be found here.

Project description

New construction of a sewer in Bad Bederkesa

Challenge

- narrow time frame

- limited space conditions

- settlement-sensitive and partly non-bearing ground conditions

- high groundwater level

Project participants

| Client / Principal | Wasserverband Wesermünde |

| Destination | Bad Bederkesa |

| Planning Office | Kleberg und Partner mbB |

| Realization | Kleberg und Partner mbB |

| Construction company | Wolfgang Heineking GmbH & Co. KG aus Bremerhaven |

egeFuse® 2.0 in Bad Bederkesa: wastewater collector completely welded and permanently tight

The new construction of a sewer in Bad Bederkesa confronted the Wesermünde Wasserverband with special challenges. The egeFuse® 2.0, a PE pipe system with integrated welding technology, saved time and costs and created a permanently tight sewer pipe system.

By Dipl.-Ing. Nicola Schlotmann, Ingenieurbüro Kleberg und Partner, and Dipl.-Ing. Jan Franke, egeplast international GmbH

The Wesermünde Wasserverband was not only confronted with a narrow time window and limited space conditions during the construction of the new sewer in the health resort of Bad Bederkesa in Lower Saxony. The special feature of this project was the soil conditions, which were susceptible to settlement and in some cases had no load-bearing capacity, as well as a high groundwater table. The experienced engineering firm Kleberg und Partner mbB was therefore commissioned with the planning for the execution of the sewage collector.

Due to its installation advantages, the egefuse® 2.0 sewer pipe system was favored. By using PE pipesystems, a completely welded and homogeneous sewer system was designed and built. As the executing construction company, Bauunternehmung Wolfgang Heineking GmbH & Co. KG from Bremerhaven was commissioned to lay the around 800 m of sewer and the associated manholes.

Saves time and effort

By reducing the number of preparatory welding measures and the amount of work required to lay the pipeline in the excavation pit, by using long construction lengths and short welding and cooling times, it was possible to complete the entire construction project in a timely and cost-effective manner.

The proof of tightness on site according to DIN EN 1610 was positively completed and the wastewater pipeline was handed over to the satisfied Wesermünde Wasserverband. The civil engineering company Wolfgang Heineking, which used the egeFuse® 2.0 for the first time, had very positive experiences with the pipe system during installation, as it is easy, fast and safe to install. The Wesermünde Wasserverband, as the client, is also very satisfied with the result of the installation.

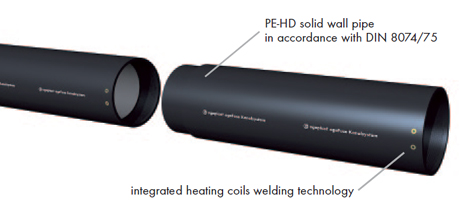

The egeFuse® 2.0

A durable solution without risks

The egeFuse® 2.0 sewer pipe system with integrated welding technology is a completely welded and permanently tight and root-resistant sewer pipe system made of PE-HD. With the patented egeFuse® 2.0 connection technology, machining (peeling work) of the welding area is no longer necessary. In addition, the recessing of the pipe support in the area of the jointing technology, as necessary with conventional electrofusion joints, can be dispensed with, since the jointing points do not apply on the outside. The integrated click technology fixes the pipe joint by longitudinal force during the welding process. Additional fixing of the joint, for example with a circumferential tension belt, is not necessary because of the conical interference fit. In the egefuse 2.0 system with integrated welding contacts, the welding parameters can be read in by means of enclosed barcodes from commercially available automatic welding machines using barcode reading pens or scanners.

The joint transition between egeFuse® 2.0 pipes is absolutely smooth on the inside and outside. There are no internal interfering socket offsets, butt edges or any constrictions, for example caused by collapsing pipe ends, which would limit the hydraulic performance. The hydraulic performance of the welded PE sewer is high due to the very low roughness values of the surface (k < 0.01 mm), making it difficult for deposits to adhere during sewer operation. As a result, the operator can extend the intervals for HP flushing, since fewer deposits and incrustations form and are easier to remove. The egeFuse® 2.0 sewer pipes also have a uniformly bright inspection-friendly inner layer throughout, which facilitates subsequent evaluation of the camera inspection of the sewer holding.

Welding with advantages

According to DVS (Deutscher Verband für Schweißen und verwandte Verfahren e.V. – German Association for Welding and Allied Processes), the welded PE pipe joint is regarded as a continuous pipe string. Investigations by the DWA and the DVGW on pipes in use for 40 years with regard to the frequency of damage to classic sewer pipes have shown that welded pipes made of PE have a significantly lower risk of damage than pipes made of traditional sewer pipe materials.

Due to the welded connection technology, a permanent root resistance as well as tightness against ex- and infiltration can be assumed. Extraneous water ingress and its wastewater treatment and the resulting additional costs at the sewage treatment plant are a thing of the past. DIN 8074 specifies a service life of 100 years for pressure pipe applications made of polyethylene (PE). At the end of its service life, 100% of the welded PE pipe string can be recycled and the recycled raw material can be used again for the extrusion of PE pipes.