Relining

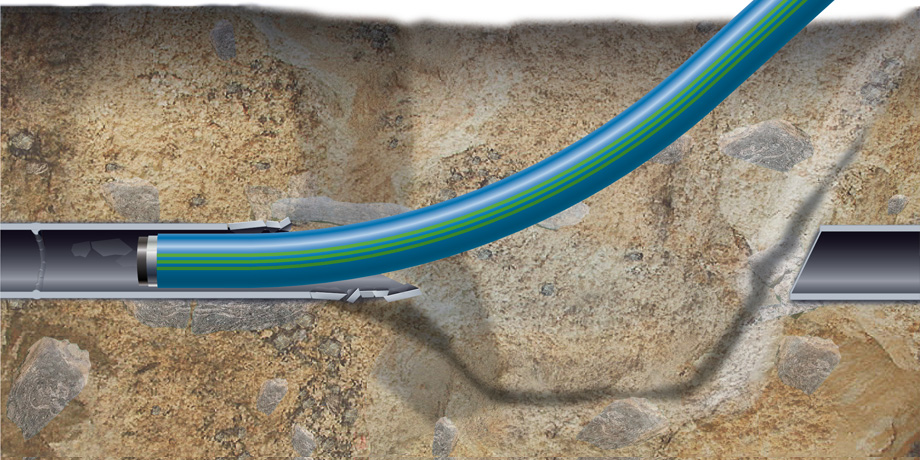

Pipe relining (DIN EN ISO 11295) is one of the trenchless rehabilitation techniques. The functionality of existing pipes is re-established using both the existing pipe structure and its alignment. Industrially pre-manufactured plastic pipes are used. They are joined to form one pipe run and are then pulled into the old pipeline.

Relining causes a reduction of the cross-section that is often desired, for example due to a decline in industry, commerce and the number of residents. Hydraulically, the new plastic pipes have relatively low resistance values. From practical experience it was established that these pipes often increase the flow rate compared to the old mains, despite a reduction in the cross-section.

The old pipeline needs to be cleaned before commencing with the relining works. The cross-section is calibrated in order to ensure that the required cross-section for the new pipe is available throughout the entire rehabilitation segment. A camera inspection of the respective segment is conducted if necessary.

The subsequent installation of the new pipe is usually carried out in construction pits with winches and traction ropes. The annular space between old and new pipe is customarily filled with grouting material. This method ensures a fixation of the new pipe on the one hand, and ensures a defined bedding of the new pipe for an equalised distribution of the loads on the other hand.

Protective layer pipes are designed to withstand the loads inherent in pipe relining and protect the core pipe from surface damages during installation and afterwards.