Ploughing and Milling

The influence of the plough on the soil is relatively slight. It is not necessary to lower the groundwater table when this method is used. This procedure is therefore extremely environmentally friendly, due not least of all to the only slight ground damage caused. The method can be used in undeveloped areas in soils up to Soil Category 5. Installation depths of up to 2 meters are possible, depending on soil conditions.

With installation rates of up to 5000 meters per day, the ploughing method is probably the most cost efficient method for installation of new pipes. The installation unit consists of the plough with the ploughshare and the installation box, and a winch mounted on a truck or caterpillar vehicle. The installation unit is drawn toward this vehicle by the winch. Once the plough reaches the vehicle, the winch is moved to the next route marking point, and the procedure repeated. In the starting pit, the ploughshare is lowered to the required installation depth. Depending on pipe diameter installation up to OD 225 mm is possible – a number of pipes can be plough installed simultaneously. The pipes are guided from above, in the trailing installation box, to installation depth. The soil closes again behind the ploughshare under its own deadweight, but this process can also be accelerated using machines. It is, it true, possible to feed sand via the installation box to installation depth, but a state of the art sandbed is not possible using this method, for technical reasons. Punctiform loads caused, for example, by stones in the soil, can cause pipe damage. To achieve the targeted minimum service lives in reality, pipes for this form of installation should consist of a material with a verified high resistance to stress induced cracking, such as egeplast 9010 RCplus, for example.

A subdivision of the ploughing method, suitable in particular for pipe materials, the permissible bending radii of which are too large for use of the standard plough, is the so called impact mole ploughing method. The procedure is identical, but the pipe is fed in in the longitudinal direction. This means that the pipe string is drawn throughout the installation length along with the ploughshare. Due to the significantly higher mechanical loads present here, the pipes need an additional external protection. It must be ensured that the permissible tensile forces acting on the pipeline and its joints are not exceeded. The length of the pipe string is limited by the tensile forces.

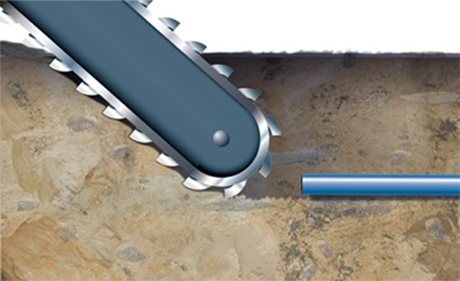

Milling:

A motor operated cutter opens a small channel of a width of up to 60 cm and a depth of up to 2.5 m. The pipe is fed into this channel, which is filled in virtually simultaneously, usually using the excavated material. Unlike the other installation methods, this method is also suitable for soils of to Soil Category 7. Rate of installation depends decisively on the predominant soil category, but is lower than in the ploughing method. The pipes used should consist of a material with a verified high resistance to stress induced corrosion, such as the egeplast 9010 RCplus, for example, since installation using this method generally does not involve installation of the pipe in a sandbed in accordance with the state of the art.