The Impact of Covid-19 on the Supply Chain

Author and at the same time head of the purchasing department for our headquarters in Greven is Evelin Maibach. This article was recently published in our egeNews.

The global crisis related to the corona virus has caused a significant drop in raw materials availability, resulting in skyrocketing prices for PE-HD accompanied by a reduction in delivery quantities. Over the last few weeks, egeplast Purchasing Manager Evelin Maibach contacted many customers to explain this exceptional recent development.

In the early time of the Covid-19 crisis in March 2020, our customers immediately raised the question how solid the supply chains were and whether supply would remain reliable in the future. At that time, irrespective of discontinuity of supply in many industries, e. g. the automotive industry, supply with PE raw materials remained secure, since the European plants continued to operate on a normal level and also because demand from some plastics processors had dropped. Twelve months later, however, things look quite different.

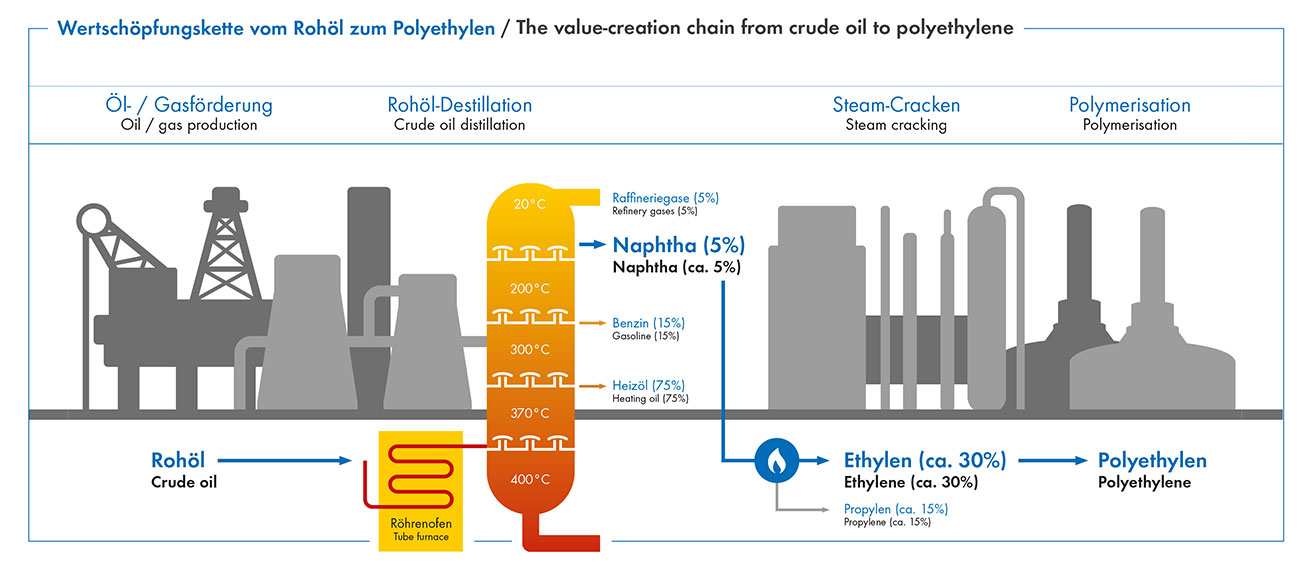

Looking back, it is obvious how, in the aftermath of Covid-19, a delayed significant supply bottleneck has now occurred in 2021. Owing to the reduced demand for PE raw materials in some industries at the onset of the Covid-19 crisis, the PE manufacturers’ warehouses were quickly full around mid 2020. So that they did whatever they could in the coming months to reduce their stocks. At the same time, the Covid-induced lockdown has resulted in a reduced demand for gasoline and diesel, and since the ethylene precursor, naphtha, is generated as a by-product in refineries, less gasoline also meant less ethylene and thus also less polyethylene on the market. As a result, polyethylene prices quickly began to stabilise again in 2020 after a temporary drop in view of full warehouses.

Reduced supply of raw material

Now, at the beginning of 2021, a reduced supply of raw materials plus emptied warehouses have come to clash with a pickup in demand in branches such as in the packaging industry, while the simultaneous demand for PE-HD in the pipe business has remained stable. Unfortunately, there is no relaxation of this situation in sight even at this point, since the refineries are still not operating at full capacity. In addition, some plants used for PE production are now about to undergo some standard maintenance measures which had not been possible in 2020 owing to Covid-19 and had to be postponed until 2021.

The resulting major shortage of available raw materials has resulted in a massive price increase along with reduced delivery quantities. In the area of pipe manufacturing, these significant price increases cannot be compensated for, since the raw material is by far the biggest cost component involved in pipe manufacturing. Unfortunately, egeplast now has had to confront its partners and customers with major price increases resulting from the 2020 Covid-19 crisis and had no option but to postpone or even cancel fulfillment of quite a few orders completely for being able to serve its existing customer base.

Author contact details

Evelin Maibach has been working for egeplast international GmbH as head of the purchasing department since the end of 2020. She has many years of experience in procurement and with her team, she is happy to face the current challenges of the plastics industry.

Evelin Maibach

Email: Evelin.Maibach@egeplast.de

Phone: +49 2575 9710 191