Sustainability at egeplast

Mentioning plastic pipes made of polyethylene (PE) and sustainability in the same breath might initially appear somewhat strange. However, plastics used sustainably to construct a long-lasting and secure infrastructure is totally different from the plastic waste to be avoided for the sake of protecting our environment and the world’s oceans. We therefore would like to let you take a peek behind the scenes of plastic pipes manufacturing, along with many interesting facts, to show you why PE pipe systems and the manufacturing process involved in producing them contribute to going easy with resources and to safeguarding our drinking water supply in the long run.

Emission-free manufacturing and 100% recycling

You will not be able to find a chimney at egeplast. To melt the raw materials, we use electrical energy – which in view of the increasing share of green electricity in Germany is being generated in more and more sustainable ways. At the same time, we use the resulting waste heat to heat buildings. Production does not result in any waste, since any potential rejects are processed and reused. This way, no industrial waste water accumulates and we do not require any disposal sites. Also, by storing commodities in our “inhouse textile silos”, we reduce the energy requirements involved in the preparation of the material. Here is an interesting comparison: The amount of electricity needed to manufacture 1 metre of pipe is as low as the average amount used up by a traditional 60-watt light bulb in 4 hours.

A climate-friendly material

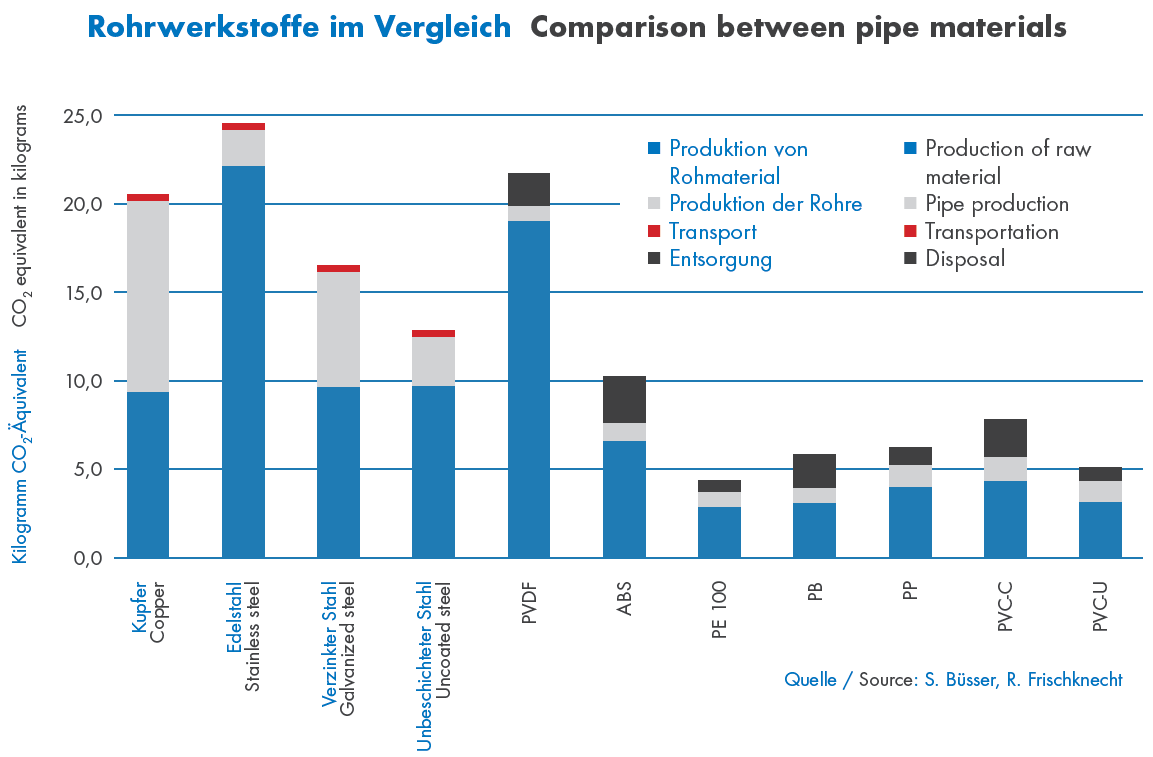

Polyethylene is made from the precursor, ethylene, which in former times used to be burnt (flared off) as “waste material” in a way which resulted in polluting the environment. Life cycle analyses have been used to assess the impact of the production of raw materials on the environment according to the ISO 14040 standard. A number of studies have shown that the CO2 footprint caused by PE pipes is significantly lower compared to the one left by other raw materials. Teppfa provides an online calculator based on a study performed by the neutral Flemish Institute for Technological Research (VITO):

www.teppfa.eu/sustainability/environmental-footprint/lca

A study performed by S. Büsser and R. Frischknecht, ESU-services Ltd. on behalf of Georg Fischer Piping Systems, 2008, provides a comparison between pipe materials