Sustainability

at egeplast

Our Goal: Sustainability for Future Generations – acting in such a way that future generations can also live in an intact world.

Our Sustainability Management

Environment

Material

Every pipe drum counts: For egeplast, the reuse of wooden drums is a practical example of resource conservation. That is why egeplast has been offering its customers a free service for years to collect empty wooden drums from construction sites. With every drum returned, a significant contribution is made to environmental protection.

Energy

Our Measures at a Glance

Resource-efficient Production with Solar Energy

With the construction of the egeGigaFab, we have invested in state-of-the-art, resource-efficient technology. Our own photovoltaic systems supply our production with green electricity.

Strengthening Material Cycles

Development of products with a higher recycled content. The egeplast Microduct egeGreen Line demonstrates how resource-saving materials and reliable performance can be combined – for example, through the use of recycled plastics.

Certified Environmental & Energy Management

ISO 14001 (since 2009) and ISO 50001 (since 2012)

Production processes for resource optimization have received multiple awards

MX Award (Manufacturing Excellence) in the category Best SME and Customer Orientation 2023, “Factory of the Year” for “Outstanding Series Production” 2022. egeplast’s commitment to sustainability and efficiency is supported by the use of 250 IoT (Internet of Things) sensors,

EcoVadis Bronze Medal February 2025

Our commitment has been recognized again – our goal is to further improve our ranking.

Digital Sustainability Reporting

In 2022, a sustainability report was prepared for the first time according to the GRI (Global Reporting Initiative) standard. For 2023, egeplast has switched its reporting to the ESRS (European Sustainability Reporting Standards) of the CSRD (Corporate Sustainability Reporting Directive). The European CSRD (Corporate Sustainability Reporting Directive) addresses various areas that egeplast handles, among other things, through integrated management systems.

Environment:

- Certified according to DIN EN ISO 14001 since 2009

- Continuous reduction of waste and use of recyclable or reusable materials

Materials:

- Reduction of water and compressed air consumption

- Reduction of packaging material and use of reusable systems

- Transition to electric vehicles

- Environmental Product Declarations / Environmental Product Declarations (EPD)

- CO2 Overall Accounting of the 3 Scopes according to GHG Protocol

- Electricity generation through own PV system and use of green electricity

- Use of PEFC certified wood, among other things

- Products with circular materials and environmentally friendly installation options

- Projects for biodiversity and employee clean-up/cleaning campaigns

Social:

- Certified according to DIN EN ISO 14001 since 2009

- Continuous reduction of waste and use of recyclable or reusable

Governance:

- Code of Conduct (Code of Conduct for egeplast employees)

- ImPROVe Program: To be able to offer our customers sustainably improved services, we have introduced the ImPROVe Excellence Program (Improvement of Processes, Resources and Organisation for Value at egeplast).

- Ethics Guideline (Guideline for our decisions and actions in compliance with legal requirements and international standards)

- Collective Bargaining Agreement for Employees

- Risk Management and Compliance

- MX Award and Factory of the Year

- Engagement of Employees and Suppliers

Employee Engagement

Sustainability is part of our corporate culture. Employee suggestions are incorporated into strategy and measures.

The Code of Conduct defines the conduct of employees and describes the corporate culture. (Link to follow)

ESG at egeplast: We view sustainability holistically – ecologically, socially, and economically

Environmental: CO2 reduction and resource conservation

Social Fair: Working conditions, comprehensive social benefits & participation, adherence to collective agreements

Governance: Transparent, future-proof structures

egeplast Plastic pipe systems

Sustainable through quality, future-proofing, and resource conservation.

egeplast pipe systems form the backbone of sustainable infrastructure. They are durable, resource-saving, and technically future-proof – and make a central contribution to achieving global sustainability goals, particularly in the areas of water supply, energy transition, and environmental protection.

Durable & Recyclable

Plastic pipes with a lifespan of over 100 years – fully recyclable thereafter

For Clean Drinking Water

Our systems ensure a hygienically sound supply worldwide.

For the Energy Transition

Infrastructure for the transport of renewable energies.

To advance the energy transition, the expansion of power grids is necessary. Underground cable routes like A-Nord will supply people in North Rhine-Westphalia with green electricity from North Sea wind farms in the future. The power cables are protected by egeplast protective pipe systems.

Intelligent pipe systems for sustainable infrastructure actively contribute to environmental protection and minimize the loss of drinking water.

For decades, egeplast has focused on developing value-added plastic pipe systems that can be installed using trenchless installation. Trenchless techniques offer ecological advantages, and interventions in nature are reduced.

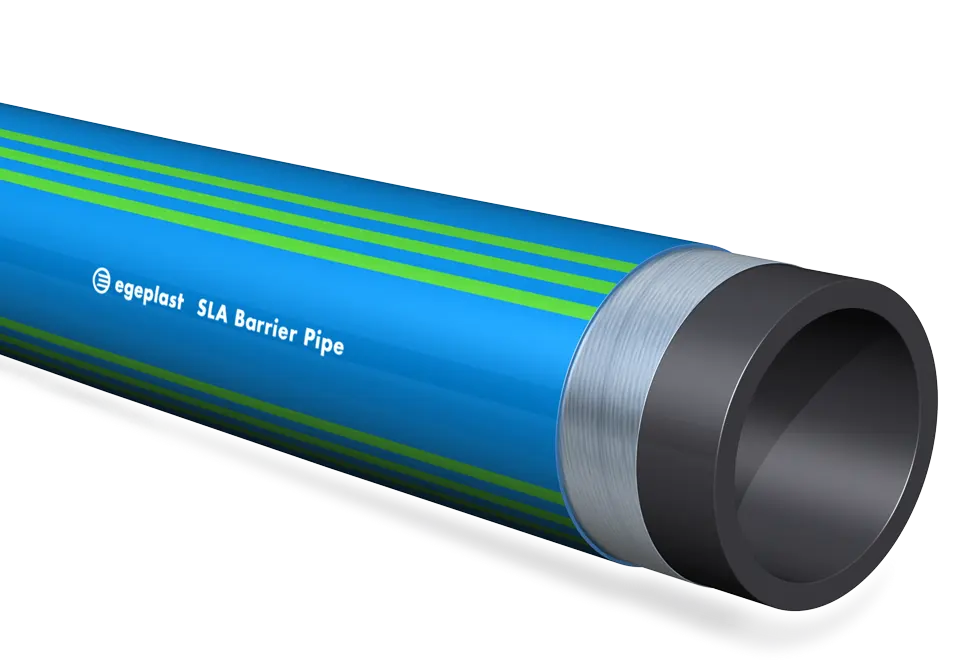

Increased Safety Requirements

Permeation-resistant pipe systems

Permeation-resistant pipe systems protect drinking water from pollutant ingress and the environment from contamination.

Monitored Pipe Systems

Monitored pipe systems prevent water losses through early leakage detection.

Transparency through EPDs

The following products have received an EPD:

PE pipes show a very good overall environmental balance – especially compared to other materials.

Energy-Efficient Production

Low CO₂ Emissions

Long Lifespan

Recyclability

Low Operating Costs

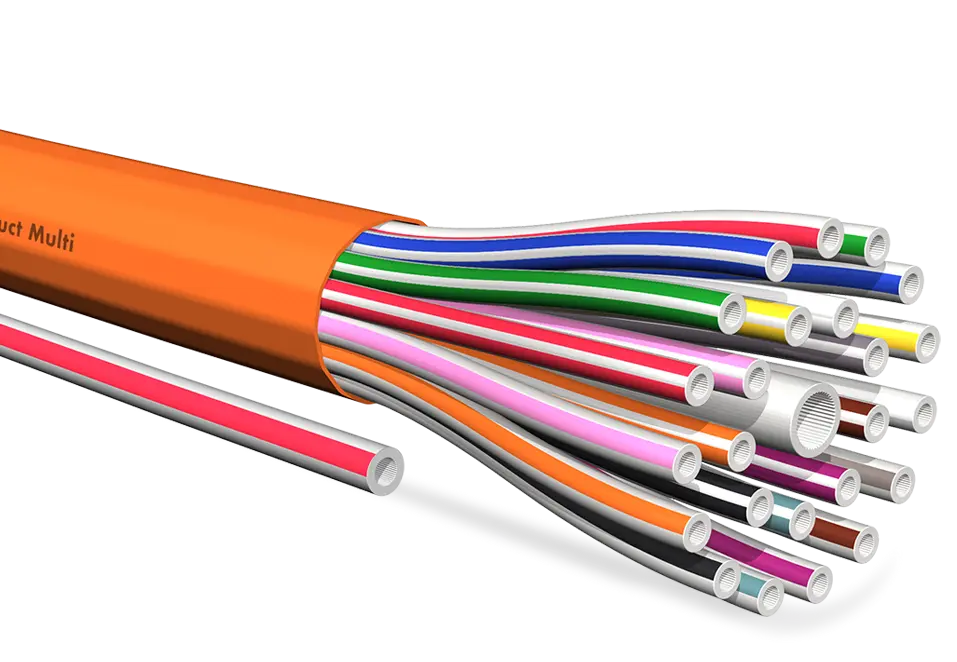

Microduct egeGreen Line - Highest Quality from up to 100% Recyclate

Sustainability in the supply chain is an important decision criterion for network operators and investors in the expansion of fiber optic networks. The focus is on environmentally friendly installation methods while simultaneously using sustainable materials.

With the Microduct egeGreen Line, egeplast offers a product range that combines ecological responsibility with technical performance. The protective pipes are manufactured from up to 100% high-quality recyclate from our own PE regranulation. They are suitable for resource-saving installation methods.

Sustainability

egeGreen Line consists of up to 100% high-quality recyclates, thus reducing the CO₂ footprint compared to conventional products

Resource Efficiency

By using recycled plastics, fossil raw materials are conserved without compromising product quality

Technical Performance

egeGreen Line meets all relevant norms and standards for microduct systems and corresponds in terms of functionality and quality to the PE variant made from virgin material

Against the backdrop of increasingly scarce primary resources

egeplast thus demonstrates how a closed

recycling loop in plastic processing

can be successfully achieved. 3R has also reported on this: