Project Report Bayernwerk: Working at High Pressure

Author of the article and client of the construction project is Peter Hößl from Bayernwerk Netz GmbH. This article was recently published in our egeNews.

For the purpose of expansion of capacity, Bayernwerk Netz GmbH from Bamberg ordered a new high pressure transport pipe for the commissioning of the Geutenreuth reference station in Weismain/ Bavaria in Germany.

Project description

Capacity expansion in the high-pressure network of Bayernwerk Netz GmbH, Regensburg

Production period

May through September 2020

Solution

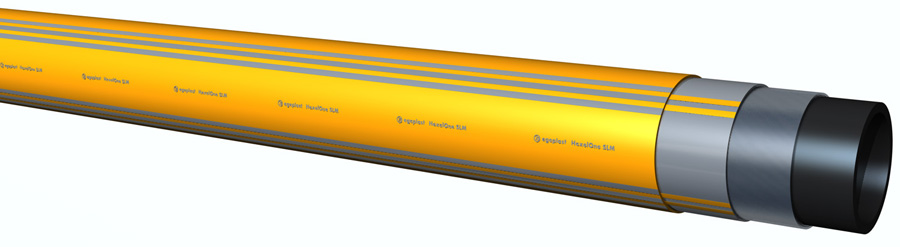

HexelOne® SLM gas pipe, OD 160 mm

Challenges

- Short construction time

- laying through rough terrain

- complex pipe routing

Installation

- 2100m using the ploughing method

- 600m applying directional drilling (HDD)

- 5 500 m using a milling process

- 600 m with an open trench

Parties involved in the project

| Client | Bayernwerk Netz GmbH |

| Location | Weismain, Oberfranken |

| Contractors | Karl Krumpholz Rohrbau GmbH, KronachRichter Bau GmbH & Co. KG, Altenkunststadt

Fräsen Schmid GmbH, Neumarkt Preißinger Bau GmbH & Co. KG, Kleinziegenfeld |

High pressure transport line of pressure stage 16 bar – HexelOne® SLM

This construction measure also involved the integration of various companies into the existing gas network, such as (among others) a mega greenhouse. The high-pressure transport pipe will transport gas with a 16-bar pressure rating to the consumers. Owing to the operating pressures required in this context, the customer selected the HexelOne® SLM gas pipe measuring 160 x 14.6 mm. The pipe run as well as the local conditions necessitated the use of different installation technologies. Needs-based application of trenchless procedures also helped to greatly reduce construction time compared to opentrench installation. Peter Hößl from Bayernwerk Netz GmbH commented: “Using the HexelOne® system enables us to reduce the total costs of construction project compared to other materials and the construction time.” The contractor who was charged with the entire excavation and pipeline work was Karl Krumpholz Rohrbau GmbH. The ploughing and milling works were assigned to selected subcontractors. Preißinger Bau GmbH & Co. KG installed approx. 2,100 m of pipeline using the ploughing technique, with the daily output reaching approx. 1,000 m. Fräsen Schmid GmbH from Neumarkt undertook the task of milling approx. 5,500 m of pipe material. The pipeline ran through a relatively challenging terrain alongside roads as well as through woody and stony terrain. 600 m were installed by Richter-Bau GmbH & Co. KG from Altenkunstadt using horizontal drilling. The remaining part of the approx. 9.000 m of HexelOne ® SLM pipeline were laid using trenchless installation. The execution of the soil and installation works was handled by Krumpholz GmbH from Kronach.

Short construction time due to long ring bundles

Reduced construction time with long coils The long delivery lengths – pipe coils at 100 m each — helped to greatly reduce the number of joints compared to other materials (approx. 100 connections versus the more than 750 connections required for steel). The permissible connection technologies for HexelOne ® SLM pipes are either combination welding or a connection achieved via compression fittings. For the long pipe segments (which had been installed using ploughing, milling or drilling), a combined welding approach was applied in most cases, a combination of butt welding and electrofusion. In the starting and target pits involved in the drilling measures, compression fittings were used to connect the individually installed pipe strings. The construction measure was closely monitored by the technical egeplast field service throughout the entire construction period. The pipeline was successfully commissioned to the satisfaction of all parties involved in September 2020 after a five-months construction period. In the meantime, more than half a dozen construction projects involving more than 30 km of the high-pressure pipe system HexelOne® SLM have been completed by Bayernwerk.

Bayernwerk – project video

The HexelOne® SLM – high pressure system made of PE

As part of the network expansion for renewable energies such as hydrogen, the construction of a pure hydrogen network is being discussed, but the admixture of up to 20% hydrogen in the existing gas networks is also a possible solution. For the infrastructure of gas pipelines, the HexelOne® high-pressure pipe system made of PE therefore enables network operators to build distribution lines economically, quickly and in an environmentally friendly manner.