SLM® DCT

Pipe system with integrated quality control

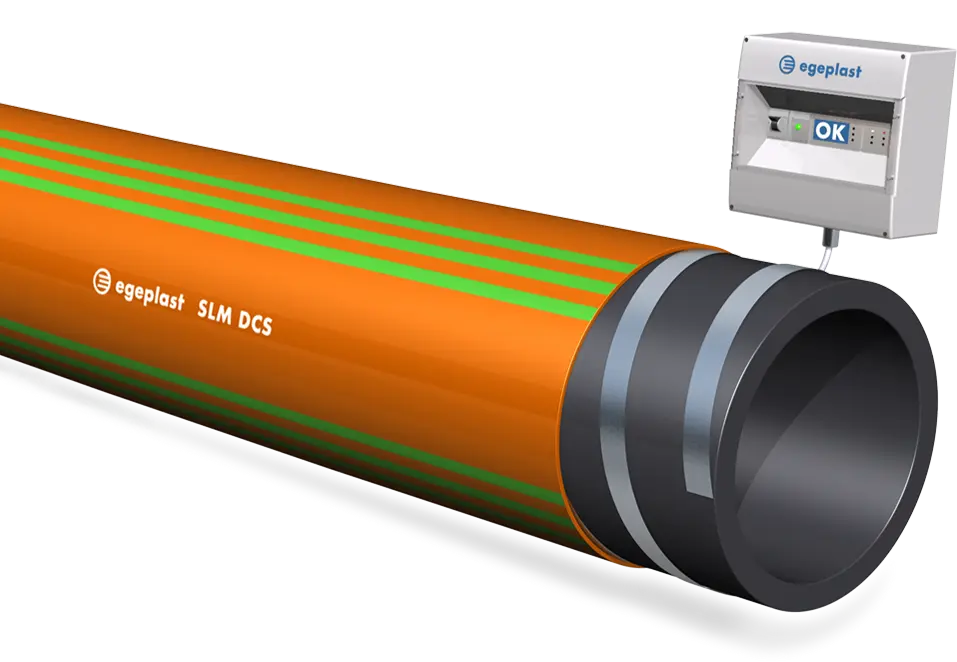

The SLM® DCT is a pipe system with an additive protective layer and integrated conductor strips for testing the pipe system for integrity immediately after Installation.

Verification of damage-free Installation after trenchless installation (integrity test)

Permanent Localization Capability

Your benefits at a glance

Maximum installation and operational safety

Enables verification of damage-free Installation immediately after Installation.

Locatability option

For quick location during maintenance, expansion or later construction work – even permanently.

Simple & safe Installation

The additive protective layer enables trenchless installation and integrity testing.

Complete system from a single source

egeplast offers a complete system, including fittings and accessories, for maximum operational reliability and cost-effectiveness.

Product video

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationConstruction site video

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

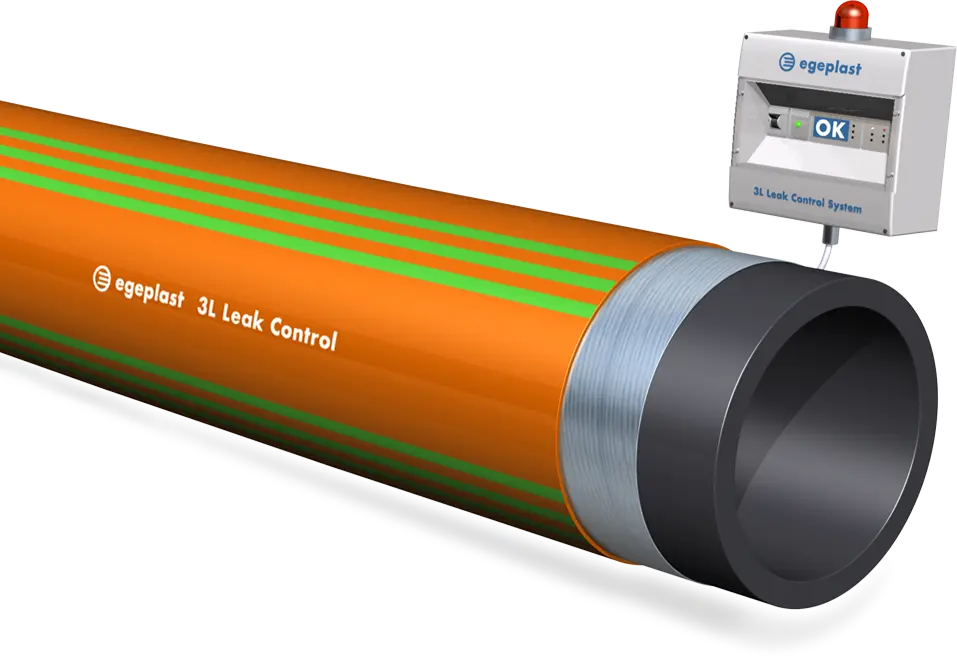

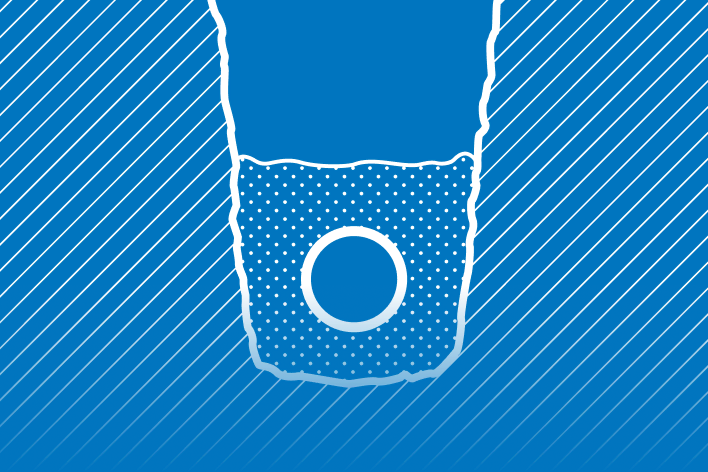

Additive protective layer made of PEplus

Conductor strips for integrity testing and Localization Capability

Core pipe made of PE 100-RC

Technical data

Dimension:

OD 25-630 mm

SDR:

SDR 7.4 | 9 | 11 | 13.6 | 17 (others on request)

Application:

Wastewater | Industrial Media

Pipe structure / Design:

Medium pipe: black, PE 100-RC

Protective jacket: modified polyethylene PEplus, brown color (for identification for wastewater/industry)

Protective jacket: modified polyethylene PEplus, brown color (for identification for wastewater/industry)

Product standards:

DIN 8074/75 | EN 12201

Testing and certification:

TÜV SÜD MUC-KSP-A 3003

Delivery forms:

Rods of 6, 12, or 20 m | Coils of 100 m | other lengths on request | Drums according to customer requirements

Installation options for

SLM® DCT

Trenchless Installation / New Laying

Horizontal Directional Drilling (HDD)

New laying with minimal impact on the environment and traffic infrastructure

Advantages

Trenchless Construction / Rehabilitation

Relining

Rehabilitation of defective pipelines by pulling in a new pipe

Advantages

Trenchless Construction / Rehabilitation

Pipe Bursting

Rehabilitation by bursting of the old pipe with potential upsizing

Advantages

Trenchless Construction / New Installation

Soil Displacement

Ideal for short, trenchless installation distances and house connections

Advantages

Low-Trench Construction / New Installation

Plowing Method

Low-trench new installation, especially for long routes in rural areas

Advantages

Low-Trench Construction / New Installation

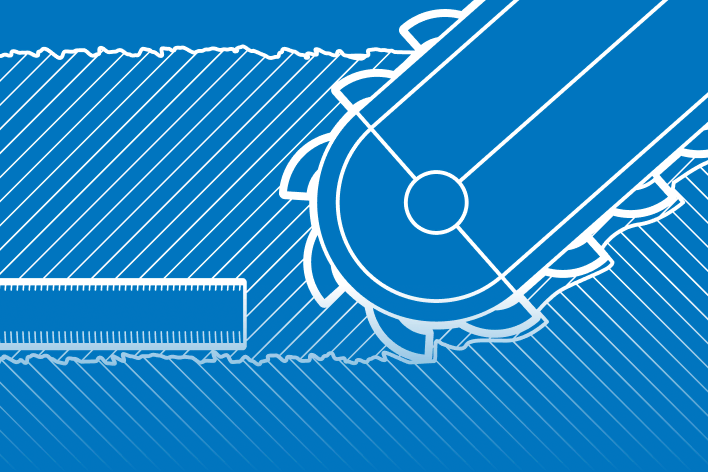

Milling Method

Low-Trench New Installation with Minimal Surface Disruption and Narrow Trenches

Advantages

Open Construction / New Installation

In the sand bed

Simple and safe new installation by bedding the pipe in sand

Advantages

Open trench / New installation

Without sand bedding

New installation with reuse of the excavated soil

Advantages

Innovative Installation Techniques

Learn more here about the diverse options for plastic pipe installation.

Learn moreReferences & Project reports

Our systems have proven themselves over decades in numerous projects. Discover our project reports.

egeFit® Fittings and accessories

Fittings and accessories matched to the system are available for the SLM® DCT: customized fittings according to customer requirements, as well as PreFab special constructions – pressure class-compliant and precisely fitting.

Other relevant products

Our solutions for wastewater technology offer a comprehensive spectrum – from standard installations to proven demanding applications in safety-critical areas.