Plastic pipe systems for industry:

safe, corrosion-free and flexible in application

Advantages of pipe systems made of PE

PE pipes are corrosion-free, chemical-resistant and offer maximum operational reliability. They combine robustness with flexibility and impress with high hydraulic performance. Thanks to their long service life, they are an economical solution for industry, infrastructure and renovation. Material combinations also enable new areas of application such as higher pressure resistance or diffusion tightness.

Industrial pipes for different requirements

Temperature resistance

For high temperatures, such as during pipe disinfection

before the flow of sensitive media or in internal

process lines and hot wastewater, egeplast

pipe systems can be equipped with temperature-resistant, integrated

layers. The egeTherm®

High-T pipe system can safely transport media up to a temperature

of +70 °C permanently and with an operating life

of 50 years.

Dissipation of static charge

When static charge is generated, pipe systems are required that safely dissipate the electrostatic charge. For this purpose, coextruded solid-wall pipes made of PE 100-RC are provided with dimensionally integrated layers of PE-EL. Depending on the application, the layers can be arranged inside or outside. A combination is also possible.

Abrasive media

In various industries, media containing solids (“slurry”) are conveyed. Due to these abrasive media, these applications place special demands on the pipe systems used in order to achieve economical operating times despite the rapid wear caused by abrasion. Pipes made of polyethylene enable long, damage-free operation with abrasive media.

Transport of sensitive media

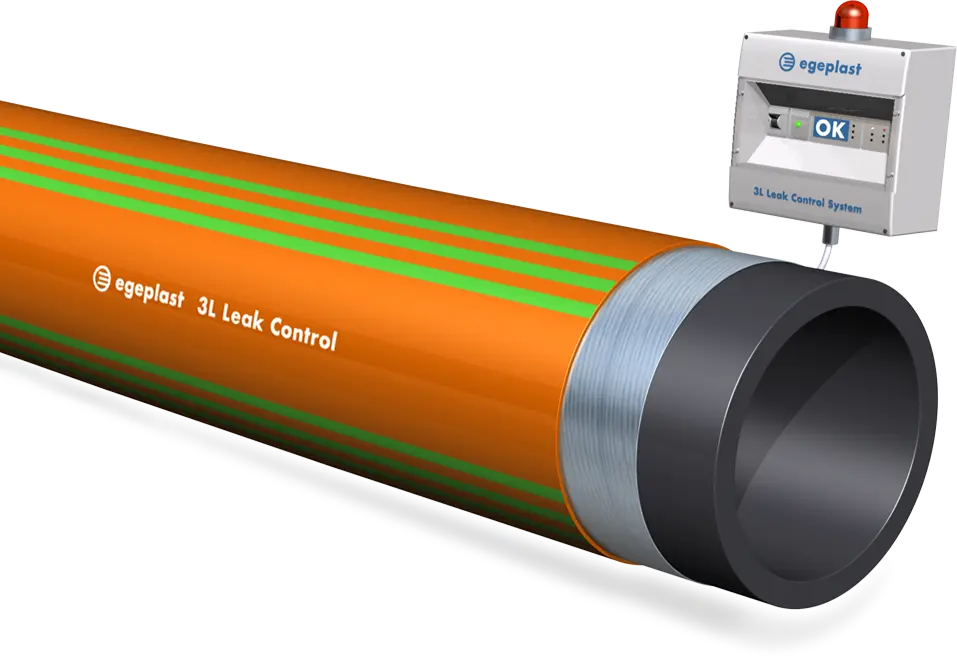

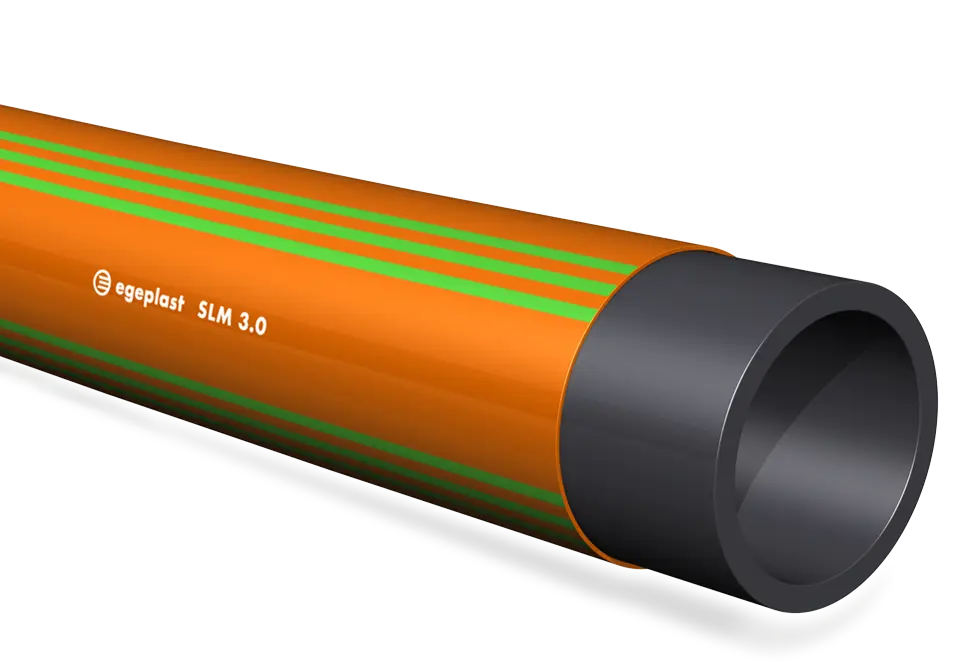

Some applications in industry require permanent monitoring for possible leaks to protect the environment and possibly to comply with legal requirements. The leakage of chemical media into the environment, possible consequential damage to people and nature, and the resulting liability risks can thus be safely excluded. An electrically conductive aluminum layer integrated into the plastic pipe enables 100 percent leak monitoring for soil and water protection.

Pressure-resistant pipe systems

In various industrial applications, pressure levels above the common applications of PE pipes are required. However, the advantages of the PE pipe, such as high flexibility, corrosion and incrustation resistance, are the prerequisite for an economical technical solution. Reinforcement layers then enable the higher operating pressures.

100% safety thanks to monitorable pipe systems

Plastic pipes with a barrier layer are ideal for applications requiring a permeation-proof pipe system. An aluminum permeation barrier reliably prevents the permeation of pollutants through the pipe wall in both directions. The metallic permeation barrier enables

the permanent protection of sensitive media and the environment. Furthermore, the electrical properties of the metallic barrier layer also enable the pipeline to be located and its integrity checked after Installation.

Chemical industry

In the chemical industry, resistance to aggressive media and maximum safety are crucial. egeplast pipe systems reliably protect sensitive processes and contribute to safe and sustainable production.

Oil and gas extraction

For the oil and gas industry, fast availability, long delivery lengths, and easy installation are important. PE pipe systems from egeplast are corrosion-free, cost-efficient, and specially optimized for the requirements of extraction and transport.

Mining

Pipelines in mining must withstand extreme loads such as abrasion and high pressures. PE pipe systems from egeplast offer a robust, flexible, and durable solution for this – even under the toughest operating conditions.