The close-fit method with pre-shaped PE pipes is a highly efficient and economical solution for rehabilitating old drinking water pipes. Thanks to the trenchless construction, high durability, and improved hydraulic properties, it offers a future-proof alternative to replacing old pipes and makes a significant contribution to the sustainability of the supply.

The maintenance and renewal of existing drinking water pipes pose major challenges for many utility companies. In addition to cost aspects, environmental factors, operational interruptions, compliance with hygiene standards, and structural restrictions play a key role. An innovative and sustainable method for rehabilitating existing pipes is the close-fit method with pre-shaped polyethylene pipes (PE pipes). This method enables cost-efficient, trenchless rehabilitation and significantly extends the service life of the pipe network. This is because the new pipe that is installed is not just a repair, but is equivalent to a new installation with a corresponding expected service life of over 100 years.

Functionality of the Close-Fit Method

In the close-fit method, a pre-shaped, folded PE pipe with a reduced diameter is pulled into the existing pipeline. Subsequently, the original shape is restored by steam pressure, causing the new pipe to fit tightly against the inner wall of the old pipe (close-fit). The process involves several steps:

1. Preparation of the existing pipeline:

- Cleaning of the old drinking water pipe to remove deposits and corrosion residues.

- Inspection of the old pipe to assess the

structural integrity.

2. Insertion of the pre-shaped PE pipe:

- The new PE pipe is initially manufactured round at the factory and then pre-shaped in a special production process so that it has a smaller cross-section.

- Due to the reduced size, it can be pulled into the old pipe with low resistance over longer distances.

3. Expansion by steam pressure or hot water:

- After insertion, the pipe is returned to its original round shape by controlled heating with steam or hot water.

- The new PE pipe fits tightly against the inner wall of the old pipe and forms a structural, tight, and statically self-supporting inner lining.

4. Cooling and pressure testing:

- After complete expansion, the new pipe cools down. After that, it is just as seamless as it is load-bearing and thus equivalent to a new pipe.

- Finally, a pressure test is carried out to ensure the tightness of all connections and joints.

The close-fit method is particularly suitable for:

- Drinking water and gas pipelines in urban and industrial areas

- Wastewater pipes with critical infrastructure, within which conventional rehabilitation measures would be problematic

- Areas with high traffic volumes where open construction would involve significant restrictions

Specialized companies are required to carry out such close-fit rehabilitations. Two partners of our company will briefly introduce themselves below:

Diringer and Scheidel

DIRINGER & SCHEIDEL DRUCKROHRTECHNIK offers innovative solutions for the trenchless rehabilitation of pressure pipelines. The traditional company uses all common, certified rehabilitation methods, including close-fit lining.

This sector now relies on egeplast’s quality products. Thanks to its decades of accumulated expertise, DIRINGER & SCHEIDEL DRUCKROHRTECHNIK can also offer tailored, single-source solutions. This ensures high cost-effectiveness and reduced construction times, while simultaneously conserving resources.

PRS

PRS Rohrsanierung GmbH is a company of the PREUSS Group. Utility companies and industrial companies have relied on the proven competence and efficiency of the PREUSS Group for over 20 years when it comes to the construction, modernization, and operation of infrastructure and plants. With close-fit lining, PRS offers an optimal inliner rehabilitation process with which pressure pipelines in particular can be renewed in the highest quality, sustainably, and in an environmentally friendly manner. Water means life – drinking water pipelines need special care. Experts must also be used for the safety of gas pipelines. You can find these at PRS! You can rely on the expertise of the rehabilitation teams at PRS Rohrsanierung.

Advantages of the Close-Fit Method

Trenchless Rehabilitation

No complex road or earthworks, which minimizes traffic obstructions and surface disruptions.

Optimized Hydraulics

The smooth inner surface of the PE pipe reduces flow resistance, improves flow capacity, and minimizes deposits.

Low Operational Interruption

Thanks to the rapid installation, the drinking water supply is maintained in many cases or is only interrupted for a short time.

High Durability

PE pipes are corrosion-resistant, chemical-resistant, and have a service life of over 100 years.

Sustainability

The process saves resources, reduces the CO2 footprint, and extends the service life of existing infrastructure without extensive new construction measures. 100% recyclable pipe material.

egeplast

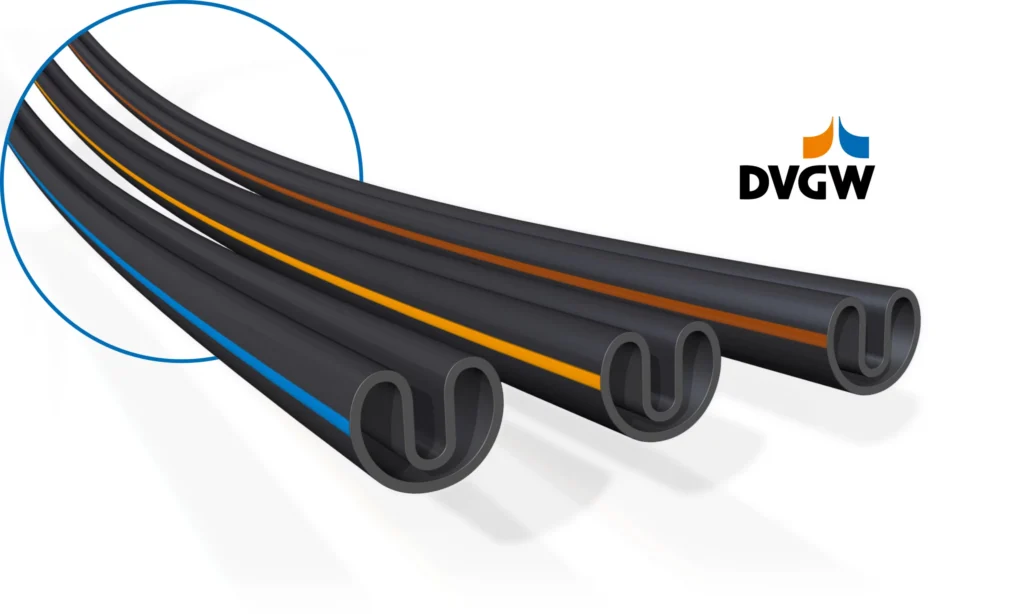

egeLiner®

The pre-shaped egeLiner® is wound onto steel drums, tailored to the length of the section being renovated. This achieves a cross-sectional reduction of up to 40 percent, allowing long construction lengths to be delivered to the site.

Fundamentally, the folded egeLiner® pipe strives to equalize the stresses frozen in its wall and transform back into its round original shape — this is referred to as the reversion process, which causes the return to the original form (“memory effect”). This property makes the close-fit method highly efficient and ensures that, after successful Installation, the egeLiner® adheres closely to the inner wall of the old pipe and can be fully integrated into the existing pipeline network without restriction.

Learn more

Learn more