Already known as a pioneer in thalassothermal energy, Monaco has set new standards with its latest project for reducing CO2 emissions. A 1.4 km long pipe system allows seawater to be pumped up from a depth of 80 m and used to operate air conditioning or heating systems — a project complex in many respects, which also serves as a good example of successful decarbonization. For secure installation on the seabed, the egeplast large-diameter pipe egeXXL was used.

Planning of the project

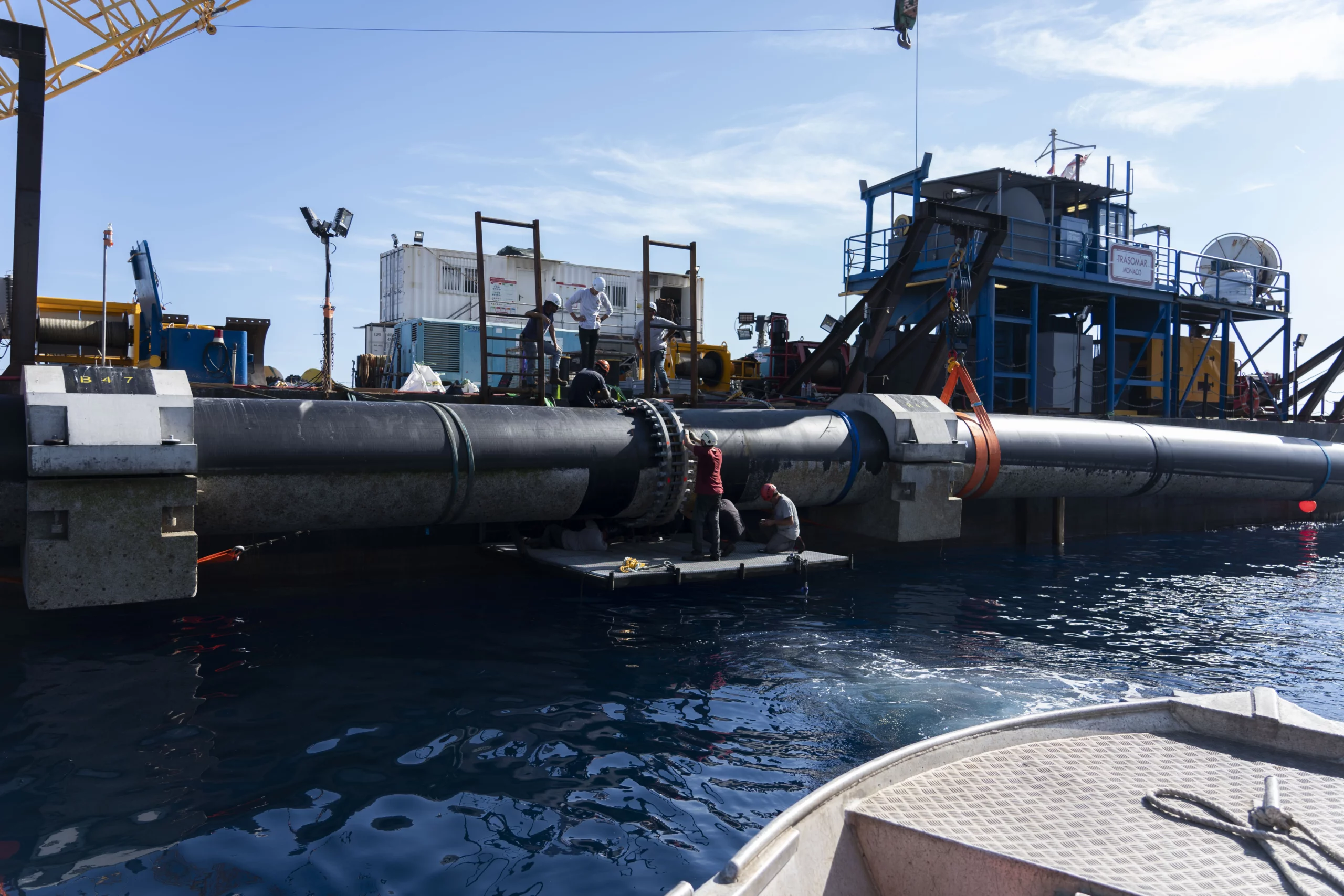

In implementing this ambitious project in Monaco, the Principality relied on the marine construction company Trasomar and the egeplast large-diameter pipe egeXXL, supplied by local dealer Reseaux Export. The welding and preparation of the pipe sections were carried out by 2A2M. The unique logistical and geographical conditions made the project a challenge at every stage. A six-month planning phase was followed by a three-month implementation phase. The project managers initially divided the 1.4 km long pipe system into four smaller sections: a starting section and three further stages, each 380 m long. These sections were prepared in the port of Bregaillon from dozens of twelve-meter-long egeXXL rods, OD 1,600 mm, SDR 21. What followed was a spectacular transport by tugboat to Monaco.

Technically Demanding Implementation in Monaco

The most delicate part, however, was connecting the flanges and lowering the finished 1,140 m long section to the seabed. This required enormous logistical effort and, in addition to precise planning during execution, was also dependent on suitable weather conditions. The lowering was carried out by filling with water from the land side. To prevent the pipes from bending, three parameters had to be carefully monitored during the process: the amount of water introduced, the back pressure, and the tension. To move the final section, France’s most powerful rescue tug, L’Abeille Flandre, was involved in the operation.

Close Collaboration of All Stakeholders Daniel Scivoletto from Reseaux Export emphasizes the quality of the partnership between the various stakeholders involved: “This project was a success thanks to the excellent cooperation between supplier, manufacturer, welder, and installer. Despite a challenging environment with the consequences of the Ukraine crisis, egeplast and Reseaux Export fulfilled all their commitments. Together with the expertise and experience of Trasomar and 2A2M, this project in Monaco was carried out in perfect compliance with deadlines and quality requirements.”

Project description

Construction of a thalassothermal system for conveying

seawater

Challenges

Offshore Installation at 80 m Depth

Solution

egeplast large-diameter pipe system egeXXL for secure installation directly

on the seabed

Installation

Transport of Pipes via Tugboat; Subsequent Lowering by

Filling with Water from the Land Side

Pipe system

1.4 km egeXXL DN 1,600 mm SDR 21 + Fittings

Project participants

Client: SAM Reseaux Export

Installation: SAM Trasomar (Sub-division of JB PASTOR group)

2A2M

egeplast

egeXXL Large-Diameter Pipe System

Large-diameter pipes up to 1,600 mm for a wide range of applications in new construction and rehabilitation

Secure, homogeneous connections through welding technology and a comprehensive range of fittings

Learn more

Learn more