Relevance of Rehabilitation

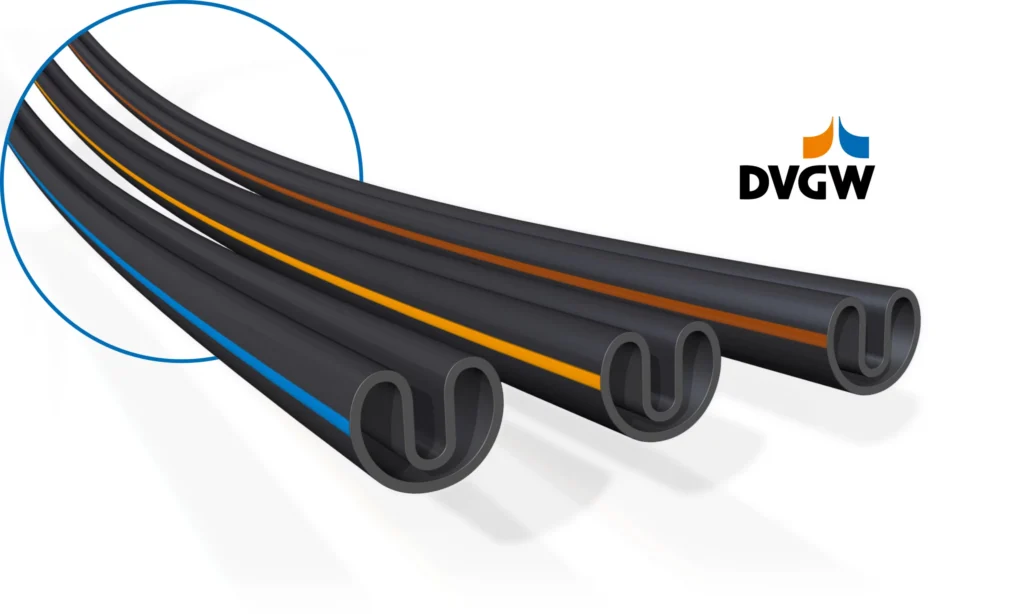

Europe faces the challenge of renovating and modernizing its old and often dilapidated gas supply pipelines. This rehabilitation is also of great importance in the context of discussions about a future transition to new gas sources, particularly hydrogen. The egeLiner® technology, where a close-fit polyethylene pipe is installed against the inner wall of existing gas pipelines, offers a straightforward solution for the trenchless rehabilitation of gas pipelines made of steel or other old pipe materials.

Implementation of the project

The construction project in the center of Prague, where steel gas pipelines in the areas of Klárov, Pod Bruskou, Kosárko-vo nábřeží, and the surrounding area were rehabilitated, was implemented in 2022 by ZEPRIS s.r.o. The construction site was located near the government seat and in the immediate vicinity of the Vltava River. The DN 500 steel gas pipeline, which was rehabilitated here over a length of 600 m, is part of the critical infrastructure. For this reason, extensive safety measures were required during the rehabilitation. Furthermore, the immediate proximity of the gas pipeline to the government seat made precise coordination essential. In this project, there was also the requirement that the backfilling of the excavation pits could only be carried out under the supervision of a fire safety officer for safety reasons.

Rehabilitations in Prague

egeplast

egeLiner®

The pre-shaped egeLiner® is wound onto steel drums, tailored to the length of the section being renovated. This achieves a cross-sectional reduction of up to 40 percent, allowing long construction lengths to be delivered to the site.

Fundamentally, the folded egeLiner® pipe strives to equalize the stresses frozen in its wall and transform back into its round original shape — this is referred to as the reversion process, which causes the return to the original form (“memory effect”). This property makes the close-fit method highly efficient and ensures that, after successful Installation, the egeLiner® adheres closely to the inner wall of the old pipe and can be fully integrated into the existing pipeline network without restriction.

Learn more

Learn more