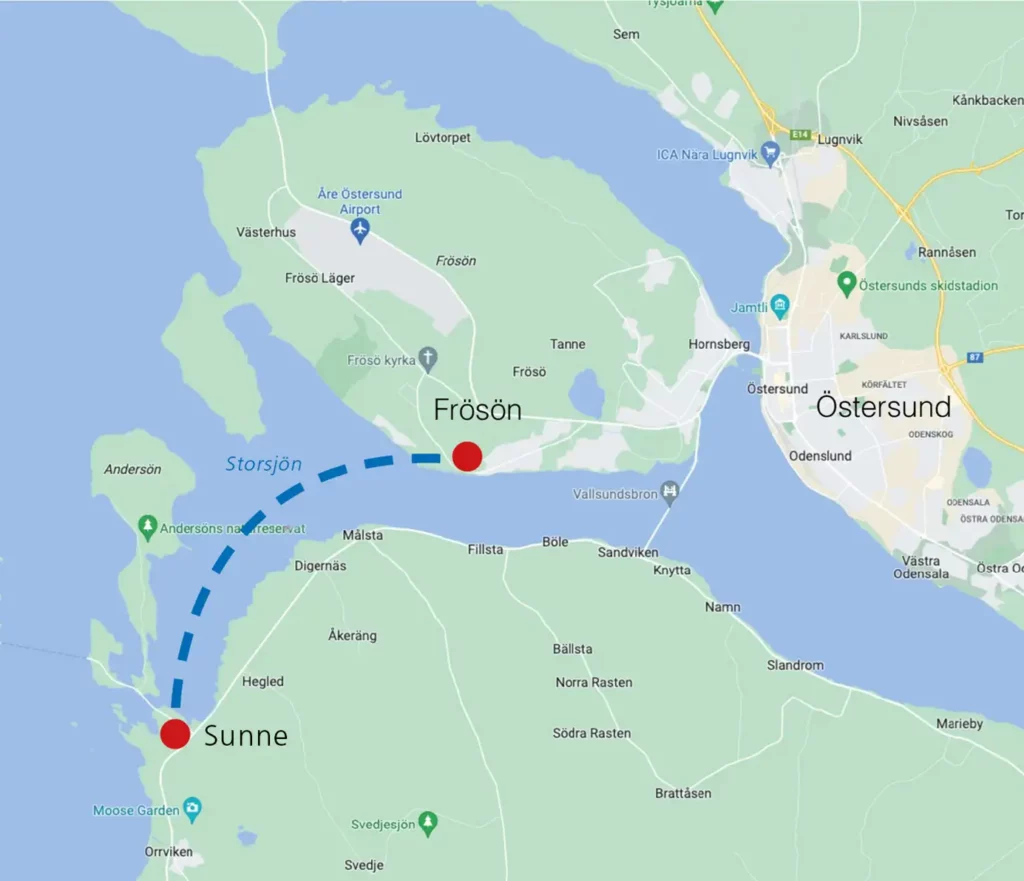

In the first half of 2023, the Swedish municipality of Östersund laid an 8 km long water pipeline between the old ferry port in Frösön and Sunne. A complex project, as the pipeline had to be laid through the completely frozen Lake Storsjön. The Extena pressure pipe made of polyethylene PE 100-RC, which is also approved according to DK VAND, was used as the pipe system.

Decisive factor: weather conditions

In addition to precise planning, the time factor played a significant role in the implementation of this construction project. This year, the ice break-up occurred unusually early, specifically on April 27, meaning the installation of the water pipeline had to be completed beforehand. For the realization of this ambitious project, the commissioned construction company Jämtland UV opted for Extena pressure pipes made of polyethylene PE 100-RC, SDR 11, and completed the project, including the connection of the land connections, precisely on schedule in June.

In times of drought, the municipality of Östersund was recently unable to adequately supply the areas in and around Fannbyn and Orrviken with drinking water. For this reason, a new water pipeline had to be built to connect these locations. “For the municipality of Östersund, it was important that the pipes we use are approved according to DK-VAND in addition to all normal approvals. This is to ensure that all requirements for drinking water pipes are met.”

DK-VAND is a product certification system that ensures that the certified products meet the strict requirements in accordance with the regulations of the Danish Ministry of Environment and Food and the additional requirements for pipes for drinking water supply, i.e. that pipes used for the distribution of drinking water do not contain any substances that are hazardous to health. So far, there is no equivalent to the Danish DK-VAND in Sweden. Therefore, the pipes are also certified according to the Danish DK-VAND in Sweden. All pipes manufactured by Extena are certified according to DK-VAND.

Spectacular Installation through Ice

Since the pipeline was to be laid on the bottom of the Storsjön, it was first welded on land, then pulled onto the ice, weighted down and filled with water to sink more easily to the bottom. The last step was undoubtedly the most exciting: after a narrow channel had been sawn into the ice along the pipe, the finished pipeline could be lowered through this opening to the bottom of the lake. This had previously been examined for possible damage risks to the pipes and prepared accordingly.

It was important that the pipes have a minimal ovality so that we could establish good and safe connections. It was equally important to choose a reliable pipe supplier so that the delivery is on time, which is particularly important for larger projects. This creates security for us as a contractor,” says Johannes Håkansson, building contractor Jämtland UV.

Project description

Installation of a new drinking water pipeline between the old ferry port in Frösön and Sunne (Sweden)

Challenges

Installation on the bottom of the frozen Storsjön legislation and guidelines within the specified time

Solution

Extena pressure pipes made of polyethylene PE 100-RC, SDR 11

Installation

Welding on land, lowering to the seabed through a channel sawn into the ice

Pipe system

Extena pressure pipes made of polyethylene PE 100-RC, SDR 11;

Dimension ø 160: 1,800 m, ø 200: 7,200 m

Project participants

Client: Municipality of Östersund

Construction company: Jämtland UV

Pipe supplier: Extena AB

Approvals

Nordic Poly Mark (Nordic quality mark)

DK-VAND (Certification by the Danish Ministry of Environment and Food)

FI (Certification by the Finnish Ministry of the Environment