egeplast egeLiner®

Factory-folded PE pipes for close-fit-lining

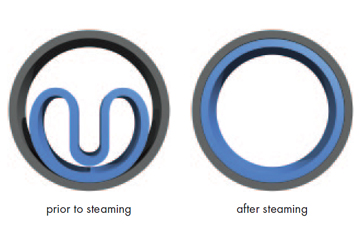

egeLiner® is a polyethylene pipe for limited spaces at the jobsite. It is deformed and folded by means of a special thermomechanical treatment during manufacture. Long lengths, even with larger dimensions, can be wound on to drums due to the reduced cross-section. For the redeformation process, the egeLiner® is warmed up with steam after installation. The memory effect activated in this way causes the PE pipe to regain its original round form. The new pipe now lies as a static independent pipe, close-fit against the old pipe.

thermomechanical

deformation/folding

Product features

- Minimum space requirement for the job site

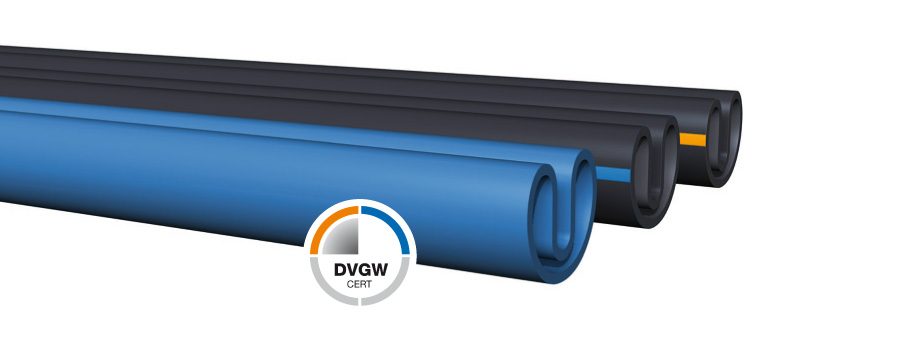

- Certified by DVGW

- Little interference in road traffic (traffic can flow almost unobstructed)

- Lower excavation costs due to pulling the pipe in via excavation pits or existing shafts

- Statically sustainable piping system

- Obtains hydraulic capacity by means of very little loss of cross-section and reduction of the wall surface roughness

At a glance

Medium

Potable water | gas | wastewater | industrial media

Material

PE 100, PE 100-RC (Resistance to crack

SDR

SDR 26 | SDR 21 | SDR 17,6 | SDR 17

Application

Rehabilitation of pressure pipes

Target Groups

Utility and disposal companies |industrial companies | construction companies

Dimension

OD 100 – 500 mm

Connection Technology

Butt welding | electrofusion | mechanical joints

Approvals

Following DVGW GW 335-A2;

INSTA SBC EN ISO 11298 (Nordic Polymark) | EN ISO 11297 | EN ISO 11298 | EN ISO 11299

Product Limitations

Pressure to PN 10 for water

Product Structure | Installation techniques

- large dimensions on drum possible

- close-fit lining