© istockphoto.com/Petmal

Microduct Green line – sustainable protection for fibre-optics without sacrificing quality

To improve their eco-balance, network operators can now rely on the egeplast Microduct Green line made of high-quality recyclates which is also suitable for resourcefriendly installation methods.

In the context of the expansion of the fibre-optic networks, sustainability in the supply chain is an important decision criterion for network operators and investors alike. Their focus is on maximally environmentally-friendly installation methods simultaneously providing the extra benefit of using sustainable materials. As innovation leaders for added-value pipe systems, egeplast therefore developed the new Green line for the telecommunications industry which is made of 100 % high-quality recyclates. In doing so, egeplast responds to the challenges involved in climate change and to an increasing scarcity of primary resources.

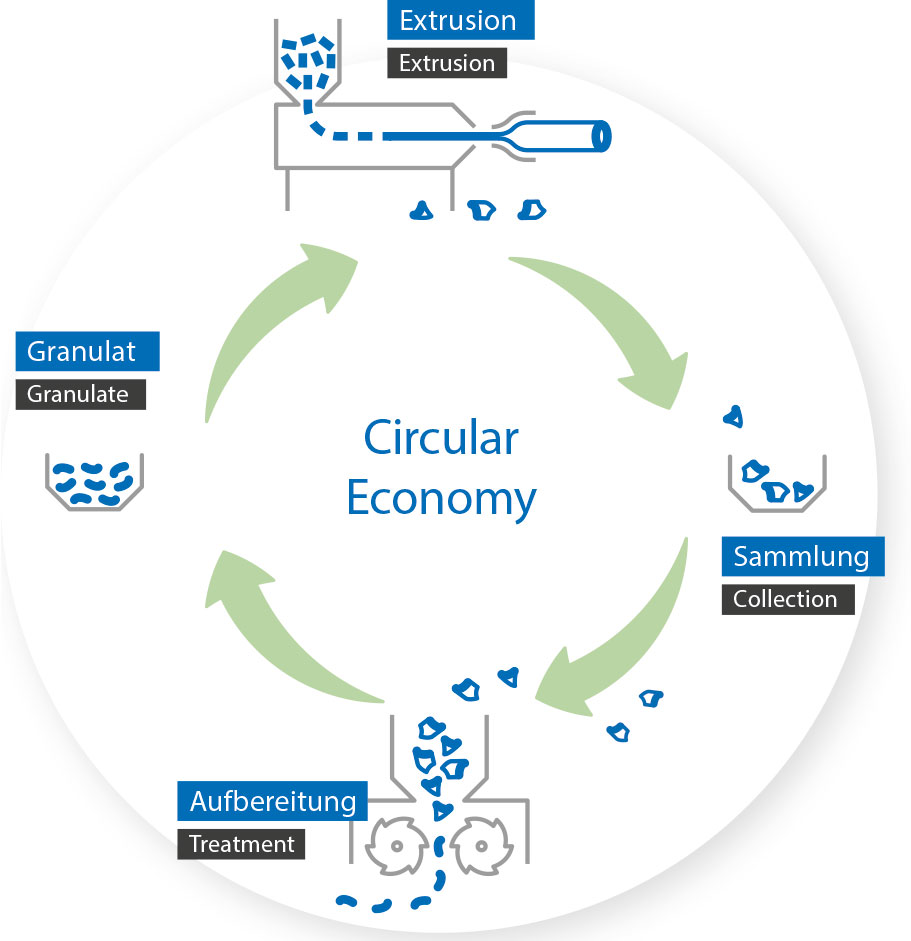

Thus the Greven-based family business is able to demonstrate how a closed-loop recycling and reuse system can be established successfully in plastics processing.

Product innovation thanks to special technology

For the new Microduct Green line, egeplast uses high-grade processed plastic materials derived from recycling. The egeplast engineers succeeded in optimizing the composition of the material in a way which ensures that the Microduct meets whatever technically challenging specifications might be involved. As a result, both the functionality as well as the quality of the fibre-optic pipe equal those of products manufactured from virgin PE. This product innovation is based on a special technology which allows for reliable compensation of any quality variations found in the recyclate used for this purpose. Ongoing material validation as well as laboratory tests and quality controls enable us to meet even the top quality standards to be heeded in order to ensure the blow-in performance required for fibre-optics.

The Microduct Green line can be connected to existing networks and is compatible with all components within any given fibre-optic infrastructure. It can be used for all common installation methods, thus also allowing for environmentally-friendly trenchless installation. This way, fibre-optic networks can be set up safely and at the same time in a climate-friendly manner. The pilot projects currently carried out with customers will be completed successfully soon.

The market launch has been scheduled for the beginning of 2023.

Contact

Thomas Fink

egeplast international GmbH

E-Mail: thomas.fink@egeplast.de

Phone: +49 2575 9710 432