Procurement in challenging times

For purchasers of pipe systems made of plastics, procurement has become significantly more difficult over the past few months. As a result of various impacts, the balance between supply reliability and the price occasionally got lost temporarily.

Uncertainties primarily arose as a result of

- Shortages and shortfalls (“Force Majeure”) in the prematerials chain and the related extreme price increases

- Brexit

- Covid-19

- Lack of chips (relevant for machinery and equipment)

- Geopolitical influences (Russian invasion of Ukraine)

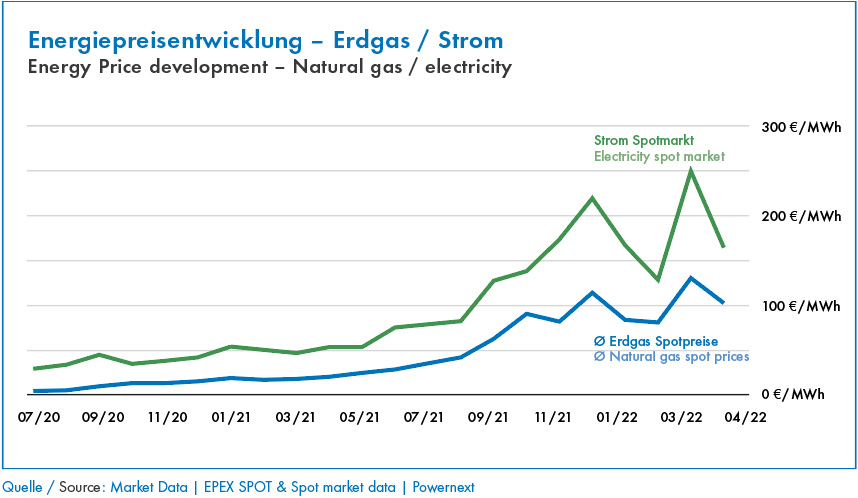

- Withdrawal from nuclear energy and coal in Germany, followed by an increase in energy costs and high level of dependency from gas as an energy source

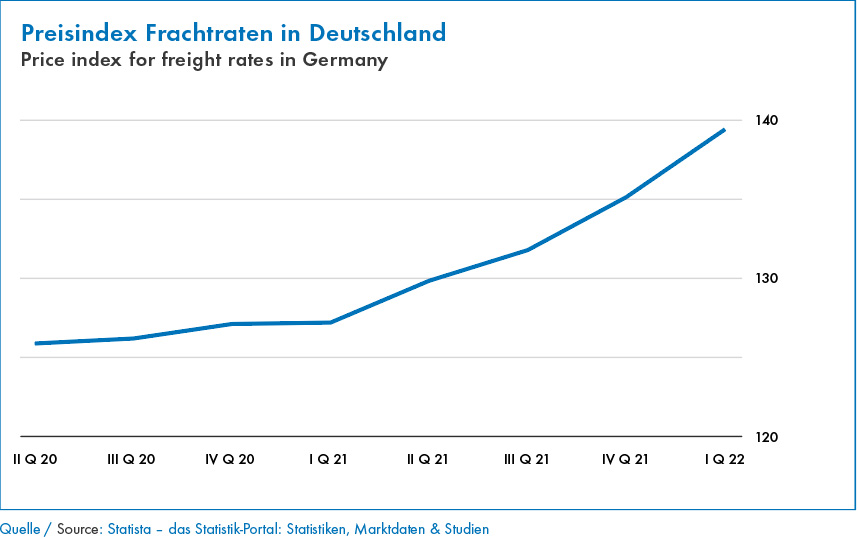

- Lack of transportation and drivers

- Potential embargo

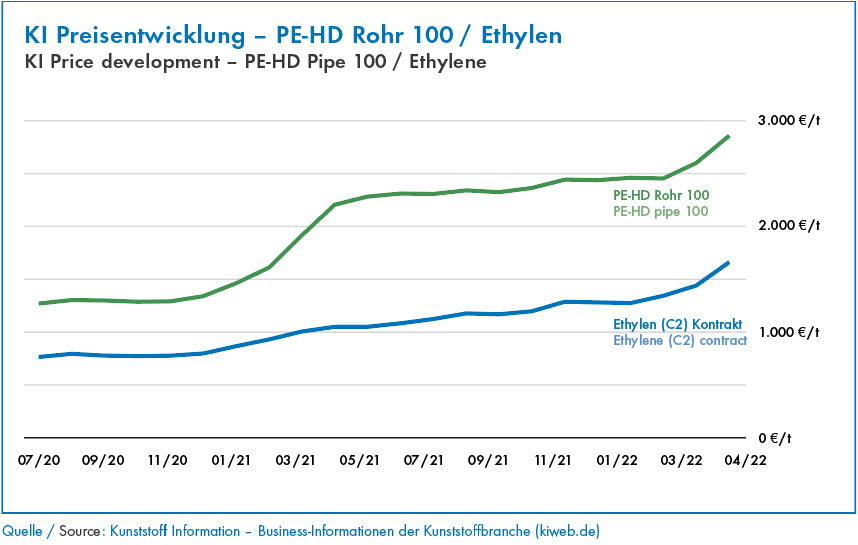

The manufacturing costs for plastics pipes, which for many civil engineering projects accounts for less than 20 % of the investment sum, mainly depends on the commodities price. The raw materials costs development over the last 18 months have been the main drivers for cost increases throughout the entire value-creation chain. In March and April 2022, price increases once again exceeded the increases of the previous months. The spread between ethylene and polyethylene has widened significantly since February 2021.

But it is not only commodity prices which have shown a dramatic increase recently, but also all of the other cost elements involved. The tables above show the trends for some cost items. Projected price trends frequently turned out to be wrong on several occasions, also those related to industry analysts. Speculations that prices would go back down caused some customers to postpone procurement transactions from August 2021, which ultimately resulted in higher procurement prices for them. For the rest of the year 2022, egeplast does not expect any lasting drop in prices.

egeplast has taken precautions in order to keep supply reliability for its customers on the level they are accustomed in spite of these challenging times:

- Inventories for strategic pre- and finished products have been increased

- Conclusion of framework contracts with the relevant raw materials suppliers stating guaranteed minimum volumes per month

- Generation of capacity in the area of extrusion in Germany, Sweden and England

- Establishment of redundancies (usually two extrusion lines per product, three extrusion sites etc.)

- Offer to customers to provide stocks for them against payment of storage fees

- Utilisation of price adjustment clauses based on the index KI pipe for long-term projects — in some cases based on mutually agreed figures forecast for the months to come

egeplast advises its customers to carry out their requirements planning earlier than previously and also to conclude long-term contracts. In the event of shortages, contractually agreed obligations always need to be met first before products are offered on the open market. For construction projects which will definitely be realised and for which you have already been awarded the order, grid operators or construction companies should order their pipes and fittings early. The delivery date of the pipes what matters for the official permits and the entire planning related to equipment, fittings and skilled personnel. In this era, supply reliability comes at a price.

Passing on of price adjustment clauses by the civil engineering company to the principal is inevitable. After all, the principal will have a structure providing 100 years of service life.

Authors contact details

Dr. Ansgar Strumann

Email: ansgar.strumann@egeplast.de

Telefon: +49 2575 9710 220