SLM® DCS allows safe transportation of treated drinking water in the municipality of Aspach

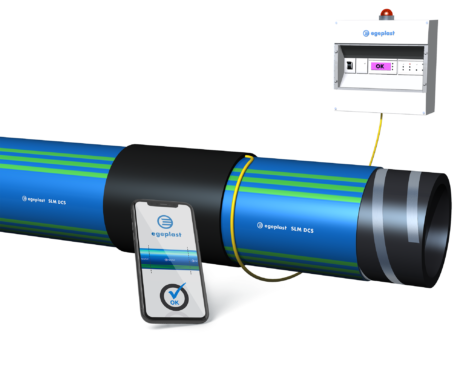

To improve the drinking water supply system, a transportation pipeline for treated drinking water was laid in Aspach, some of it in an open-trench manner without a sand bed, and some of it using horizontal drilling. To avoid water losses and to ensure a rapid response in the potential event of a damage, the SLM® DCS pipe system, which allows for continuous monitoring, was applied.

A concept for a water supply system of the Rems-Murr district

On the basis of a comprehensive plan for a water supply system, a number of municipalities joined forces with NOW (the Special Purpose Association of Water Supply in Northeast Wurttemberg) and decided to realise a joint project aimed at improving drinking water supply in the Northern area of the Rems-Murr district. In addition to NOW, the project is sponsored by the municipalities of Oppenweiler, Leutenbach, Allmersbach im Tal, Aspach, Burgstetten and the Backnang Public Utility. The plan involves bringing the water of each of the partners involved together and treated at the Murrtal NOW waterworks via raw water pipelines before being redistributed to the municipalities. The plan is subsidised by the State of Baden-Wurttemberg.

In the municipal district of Aspach, the pipeline route starts north of Rietenau at the elevated tank, and from there it runs past the north of Allmersbach a. Weinberg to the pump station at Einöd. The transporation pipelines are 4.5 kms long. The total length of the pipelines to be installed for raw water and clean water is 9.5 kms. Along the route, the water pipelines are laid across agricultural roads, across meadow orchards, on farmland and in later segments multiple times through wine-growing districts, which in view of the very confined space condition in the vineyards constituted a challenge for construction site logistics. The option to include sand bedding was dispensed with. For most of the construction measure, open trench installation applies. In two sections, the pipelines were installed by means of horizontal drilling.

Realtime report to the control station

“The system provides the opportunity to continuously monitor the pipeline. If a damage occurs, the monitoring unit will report it to the control room at the NOW headquarters in real time in Crailsheim and enables us to assess the site of the damage with one-meter precision and to repair it”

One of the problems involved in pipelines of this length is that leakages that using conventional measurements of the differential between the input and output counters is that potential leakages might only be detected at a very late point in time and just indicate that the pipeline may have been damaged — meaning that they leave room for interpretation and fail to provide any reliable information related to an actual damage of the pipeline. Apart from that, in many cases, localising and fixing a leak by these means is very difficult and comes at great expense in terms of time and labour input.

To prevent water losses and to allow for quick responses if a damage occurs, the Special Purpose Association of Water Supply in Northeast Wurttemberg, following consultation with the municipality of Aspach, decided to execute all pipelines in construction phase 3.2.2 using the SLM® DCS pipe system. “The system provides the opportunity to continuously monitor the pipeline. If a damage occurs, the monitoring unit will report it to the control room at the NOW headquarters in real time in Crailsheim and enables us to assess the site of the damage with one-meter precision and to repair it”, says Marco Düring from Zweckverband Wasserversorgung Nordostwürttemberg.

Authors contact details

Marco Düring

Tel.+49 7951 481 514

m.duering@now-wasser.de

Marc Wewers

Tel. +49 2575 9710 222

marc.wewers@egeplast.de