SLA® Barrier Pipe for the protection of drinking water: More than 30 years of successful application of the original made by egeplast

The SLA® Barrier Pipe made by egeplast is a safe and proven solution to ensure clean drinking water for piping systems in contaminated soil. With its 30 years of practical application, egeplast provides an all-in system including the matching jointings for fast and easy installation i. a. for horizontal drilling.

As early as in 1984, the question arose how the many benefits of polyethylene plastics pipe systems with regard to installation and operational safety might also be put to use in contaminated soil and applications where pipings are required to remain in use for more than 50 years. In the Netherlands, taste was found to have become compromised over such a time period in some cases where standard PE pipes had been installed in heavily overfertilized soil.

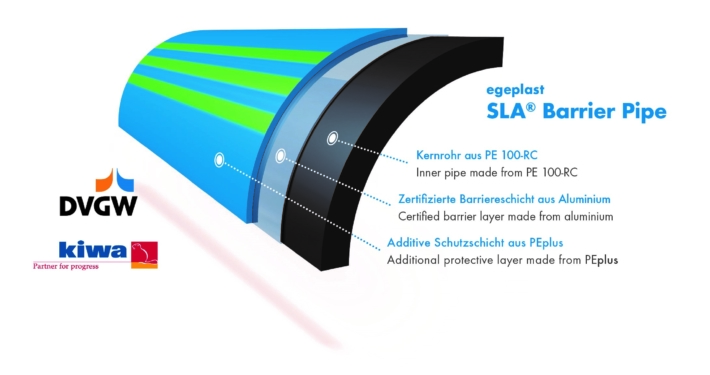

Displaying the drive of a real innovation leader, egeplast began to develop the first protective tube of the time, which since that time has undergone further evolution continuously, leading up to the development of today’s SLA® Barrier Pipe System. When it became available, this innovation enabled customers to use multi-layer pipe systems made of polyethylene for modern civil engineering projects even in heavily contaminated soil efficiently and in an economically advantageous way for the first time ever. The additional aluminium layer that these pipes are equipped with rules out any penetration of hazardous substances into the inner pipe, thus protecting drinking water from contamination.

In 1988, following extensive testing and developing, the Dutch testing institute, KIWA, created the first test basis ever for PE pipes with a diffusion resistant aluminium barrier layer which served to expand the then current state of the art: “Test procedures for assessing the permeability of aluminium laminated pipes”. It was to become the basis for the currently applicable BRL 17101 which provides the basis for the certification of barrier pipes featuring a barrier layer made of aluminium, the requirements of which are fully complied with by today’s SLA® Barrier Pipe even for the highest protection class, III.

Together with a number of international partners, egeplast also succeeded in designing precisely matching and reliable connectors. For example, one of them, Conval, launched matching brass connectors onto the market in the Netherlands as early as in 1995 which were also certified by KIWA. Innovations also involved a suitable method for creating reliable and flexible post-factory coatings related to the welding of the pipes which would also work reliably when applying the horizontal drilling approach. In addition, egeplast provides the entire range of fittings such as bends and T-pieces as system components and is able to also provide customized components with an aluminum barrier layer in its own fittings department.

This evolution reflects decades of experience with SLA® Barrier Pipe Projects. Now as then, egeplast customers are thrilled about the high quality of the SLA® Barrier Pipe System and continue to apply it just like it was applied in 1995.

The SLA® Barrier Pipe has many advantages compared to other solutions:

- Certified for the highest KIWA protection class III

- Manufactured according to the PAS 1075 standard

- Tested according to the highest sanitary standards (e.g. DK Water)

- All-in system incl. bends, tees and proven pipe fittings

- Eco-friendly installation, cost and time benefits thanks to trenchless and nearly trenchless installation methods

- Tailor-made solutions by means of different combinations of materials for different applications and according to customer specifications (e. g. for difficult soil conditions, colour-coding indicating the transported medium)

- Protected transportation of drinking water and sensitive media through areas in risk of contamination

- Protection from environmental hazards by means of safe transportation of media involving media which might be harmful for water and the environment as well as chemically polluted effluent and process water and hazardous gases

- Long delivery lengths (several 100 meters depending on the dimension), low weight

- KIWA confirmed barrier properties – even in tests with substances such as trichloroethylene (TCE)

- Weather and seawater resistant aluminium barrier layer

We are intent on continuing our mission of clean drinking water and the success story of 30 years of SLA® Barrier Pipes. What are your challenges or which questions do you have?