A new drinking water pipe for a trendy neighbourhood in Amsterdam

In the course of extending the drinking water supply network on a former shipyard in Amsterdam, the egeplast SLA® Barrier Pipe was installed applying trenchless installation and horizontal drilling. When water bodies needed to be underpassed, the pipe was weighted during installation. The impermeable pipe system has been certified by KIWA for carrying drinking water.

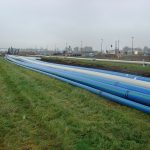

The drinking water project at Amsterdam’s Grasweg has been completed successfully by van Leeuwen Boring Bros. In cooperation with BAM Infra energie & Water. The former NDSM shipyard in the North of Amsterdam had evolved into a cultural hotspot, with an ever-increasing number of bars, restaurants and artists’ communities. To expand the drinking water

distribution network, a new egeplast SLA® Barrier Pipe for drinking water with an OD of 500 mm and measuring 770 m in length was pulled in using the horizontal drilling method.

To protect the drinking water on the former shipyard premises, the impermeable SLA® Barrier Pipe was selected. This pipe system, which is equipped with a protective layer, reliably rules

out any permeation of pollutants and has thus been certified by Kiwa Nederland B.V. for transporting drinking water as a PE pipe system with an aluminium barrier layer. Damage-free

installation of the pressure pipe in the context of trenchless installation is ensured thanks to its special additional protective layer.

On site, the 20 m-sticks were connected using butt welding. Eleven telescopic cranes and several mobile crane systems helped to guide the tubing to the starting pit via access roads and walkways in a controlled manner. At the starting pit, drilling was initiated and the SLA® pipe run below the harbour basin. To counteract the buoyancy caused by the air in the pipeline and thus reduce the amount of resistance which was to occur when pulling the pipe in, the pipeline was weighted down. To reach this added weight, a second pipe was inserted and filled with water. “After five hours, the SLA® pipe had arrived at the target pit and drilling had been completed successfully to the utmost satisfaction of all parties involved”, the site manager John Henzen of van Leeuwen Bros. commented. BAM Infra Energie & Water documented the construction project on camera. Check out the video on www.egeplast.eu/egeplastube.

As of now, the SLA® Barrier Pipes , which come with a barrier layer made of aluminium, have also come to be approved and awarded the KIWA certificate for highly contaminated class-III soils. The protective layer system reliably rules out any permeation of contaminants and has thus; as a PE pipeline system with an aluminium barrier layer; been certified by KIWA Nederland B.V., as suitable for carrying drinking water. It ensures damage-free installation of the pressure pipe for trenchless installation methods such as horizontal directional drilling by means of its special extra protective layer.

Contact

| Marcel Leerkes Conval Nederland B.V. Tel: +31 411 67 47 25 Leerkes@conval.nl |

Michael Dick egeplast international GmbH Markt Manager Niederlande Tel: +49 2575 9710 243 michael.dick@egeplast.de |

Would you like to be kept up-to-date with the latest news anytime?