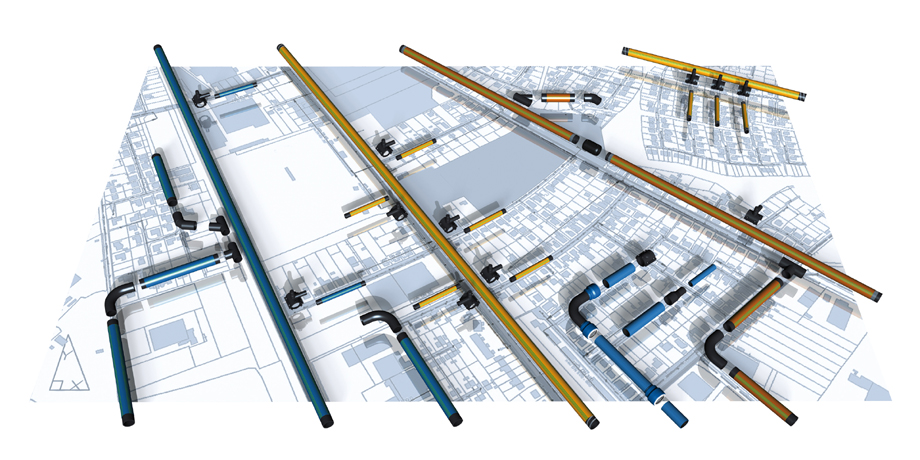

A full system provided by a single supplier as well as numerous service functions make project design and implementation involving egeplast plastic pipe systems easy to handle. To achieve this goal, egeplast offers planners a system complete with pipes as well as the matching fittings and components tailored to customer needs.

RFP forms

RFP forms for pressure pipe systems

RFP forms for gravity pipe systems

RFP forms for cable protection systems

egeplast provides pipe systems for almost any application. Your area of application has not been mentioned? Approach us to develop a solution tailored to your requirements.

egeplast services

Preliminary project planning

Support in selection of installation methods –

trenchless vs. standard installation

- Cost comparison of the installation methods

- Selection of pipe materials depedning on installation method

- Usage of norms and standards

Project planning

Technical consulting and advisory services for the planned project

- Recording of customer demands (pressure, route, time, conditions)

- Selection of materials

- Selection of installation method

- Product seelction

- Classic PE consultation: life cycle, connection technology, tensile force, trench lengths, etc.

Commercial consulting

Commercial consulting and advisory services for the planned project

- Material costs

- Projekt costs

- Cost of Ownership

Implementation

Active support during the project implementation phase

- Construction site show-how (egeplast pipe systems)

- Site management during all project phases

Follow up

Services at conclusion of the project

- Assessment of economic efficiency

- Pipe material assessment

- Documentation

- Documentation of the materials and certificates

Welding equipment rental

Seminars

Planning of pressure pipe systems made of polyethylene

- 88 pages of expert knowledge

- Free

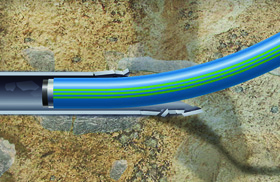

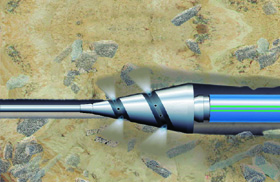

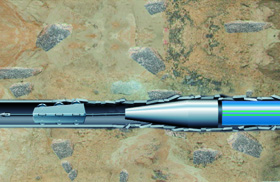

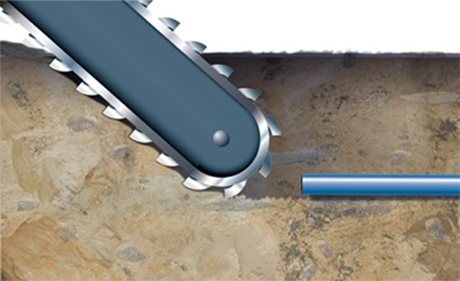

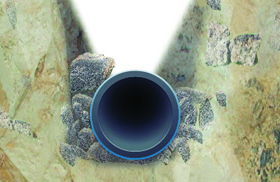

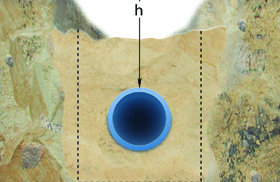

Installation Methods

Supply networks today at least in Germany virtually extend across the entire country. For this reason replacement and renovation, in particular using closed installation methods, are of greater significance than new construction. With all trenchless installation methods, there is an increased risk of pipe damage. The extent of this damage cannot be determined once the pipe is laid (black box installation!). For this reason, pipes with a protective outer layer are required and are therefore recommended by the DVGW. It is possible to differentiate in the context of installation methods between installation with or without a sand bed and trenchless methods. A large range of alternatives has developed in recent years for no-dig installation methods; these are examined in detail below.

Certifications

To ensure a permanently high quality, egeplast pipe systems are tested by well-known institutions regularly. The pipe systems have been approved by licensing bodies such as:

Furthermore, egeplast as a company has also been certified according to the DIN ISO 9001 (Quality Management), DIN ISO 14001 (Environmental Management) and DIN ISO 50001 (Energy Management) standards. Check out the certificates in question on this website.

References

Professional articles (german)

gwf (Issue 01/2016)

Intelligente Rohrsysteme durch smarte Kombination verschiedener Werkstoffe

Author: Dr.-Ing. Thorsten Späth

Energie Wasser Praxis (Issue 10/2014)

Schutzmantelrohrsysteme für geschlossene Bauweisen

Energie Wasser Praxis (Issue 07/08 2011)

Erweitertes Anwendungsspektrum von Kunsttoffrohren in der Wasserversorgung durch moderne Mehrschichtrohre

Author: Dr. Thorsten Späth

More professional articles can be found here.