Processing GuidelinesDo you need assistance with the installation of egeplast plastic pipe systems? egeplast provides detailed installation guidelines for every pipe system. |

|

Processing videos

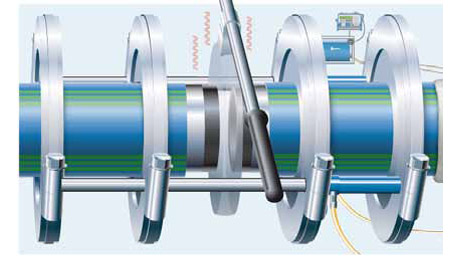

Processing video SLM® DCT post-factory coating

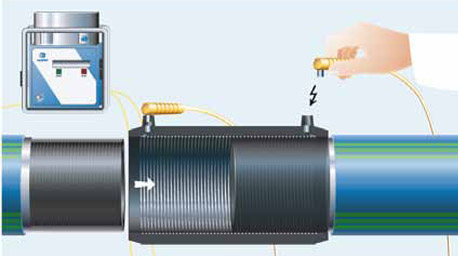

Processing video egeConnect welding socket

egeplast Services

|

|

Components / special constructions

|

Welding machines and equipment hire

|

|

|

Implementation

|

Seminars

|

Videos from construction site

Construction site video SLM® 3.0

Construction site video egeLiner®

More videos can be found here.

Joining Techniques

Polyethylene pipes and pipe components can be joined with one another either thermally or mechanically. The most important thermal methods are butt welding and electrofusion welding. Welded piping systems are absolutely tight and do not require any additional sealing elements. The most important procedure for joining of HDPE pipes is butt welding. Here, the surfaces to be joined are heated, after corresponding preparation (cleaning and flattening of the pipe ends) to welding temperature on a heating element and the pipe ends thus plasticized are, after removal of the heating element, forced together under pressure. Welding takes place in accordance with specified process operations, which are documented in DVS 2207. Bell and socket and clamped joints are mechanical joining methods which are used primarily for building service connections.

Butt welding |

Electrofusion welding |

Download of the SLM® 3.0 welding tables

Applications | Pipe systems

egeplast provides pipe systems for almost any application. Your area of application has not been mentioned? Approach us to develop a solution tailored to your requirements.